Hello Everyone,

Those traveling through Amish Country discover numerous restaurants and stores worth visiting. While at these places, take time to browse their brochure racks pointing you to additional places to explore throughout the area. Then take some of this information, read it, and check out what interests you.

Besides those mentioned in part one, here are other places we recommend. For prize winning cheese, stop at Guggisberg Cheese in Charm, Ohio. This company originated Baby Swiss cheese and has consistently won national and state awards for its premium Swiss. Its delightful restaurant, across the street, features Swiss/Austrian dishes and atmosphere. Wendell August is THE place to go for hand forged gifts. We asked the Amish and learned they often choose Mrs.Yoders Kitchen in Mount Hope when eating out.

GUGGISBERG CHEESE

Alfred Guggisberg, the founder of Guggisberg Cheese, was only 16 when he started studying the art of cheese making in Berne, Switzerland. To further his education, he attended the famous Swiss Federal “Molkereishulle” (cheese makers’ institute) then practiced his craft in Europe and Africa for many years. Upon his coming to Ohio in 1947, Amish farmers convinced him that Charm, located in Ohio’s Doughty Valley, was the place for him to practice his craft. He purchased Doughty Valley Cheese which evolved in 1950 into Guggisberg Cheese.

In the 1960's, his goal was to develop a new style of Swiss cheese that Americans would prefer. He had noticed the American palate differed from that of Europeans when it came to enjoying the strong taste of traditional Swiss cheese. His new cheese had smaller “eyes” (holes) and a creamier taste.

Alfred’s wife, Margaret, called it “Baby Swiss” after she saw a wheel of it next to the much larger wheel of traditional Emmental Swiss. Baby Swiss launched in 1968 when Margaret approached the local grocery store chain, Buehler’s, a company which remains a regular customer of this product. Competitors have imitated Baby Swiss but never duplicated it since they lack the family recipe.

Under Alfred’s son, Richard Guggisberg, current company president, it has become one of the larger manufacturers of Swiss cheese in the United States and one of the biggest cheese manufacturers of any type in Ohio. The company sells to retail and wholesale customers all over Europe and the United States.

The third family generation is now involved. At Guggisberg, we met Ursula, Alfred’s granddaughter, who is marketing coordinator for the company.

In 1995, Guggisberg opened a new plant in Sugarcreek, Ohio. That same year, the Doughty Valley factory was remodeled and old equipment replaced with state-of-the-art technology. Sugarcreek's plant, specializing in the production of 200 pound blocks of traditional cheese, produces a much higher volume than Doughty Valley’s factor but isn't open to the public.

Guggisberg sells more than 60 varieties of cheese which you can sample at their gift shop. Their biggest seller is Baby Swiss. Amish butter cheese is similar to a Haverti since it is high in butter fat and very creamy. Lacerne, another type of Baby Swiss, is low in fat and sodium. Farmers Cheese is made partly from skim milk, has the texture of mozzarella, and the smooth finish of Swiss. Guggisberg also sells Swiss lace cheese and Emmental Swiss cheese.

To go along with several cases of cheese, you’ll find in their gift shop such meats as summer sausage and bologna; complements such as crackers, mustards, jams, and fudge; and cheese knives and spreaders. The shop also carries Amish and Swiss themed goods. Travelers will find everything from cuckoo clocks to Swiss chocolates.

THEIR AWARDS

Guggisberg has won numerous awards over the years. In 2017, it received first place at the U.S. Companionship Cheese Contest for premium Swiss and second place in that contest for Baby Swiss. It also won first place for its cheese in the Ohio Dairy contest.

In 2016, Guggisberg received first place in the World Championship Cheese Contest for premium Swiss. Hosted by the Wisconsin Cheese makers Association, it alternates every other year with the United States Cheese Championship. It’s the world’s largest technical cheese, butter, and yogurt competition. The 2016 competition had 2,948 submissions from 23 countries. Guggisberg also took second, fourth, and fifth place with additional entries in the Swiss style category.

During 2015, the company received numerous awards. This included being United States Grand Champion at the United States Cheese Championship with entries from 28 states. More than 33,000 pounds of dairy products were entered into the contest which dates back to 1891 by the Wisconsin Cheese Makers Association. It’s one of the country’s most prestigious competitions.

In 2016, Guggisberg also won Ohio Grand Champion Cheese maker for premium Swiss. In the 2015 American Cheese Society contest, it won first place for Baby Swiss and colby and second place for Emmental Swiss. It was awarded third place in the U.S. Cheese Championship for colby.

In addition, Guggisberg has been awarded Ohio Swiss Cheese Association’s Grand Champion Cheese maker from 2011 through 2016 at the Ohio Swiss Festival’s cheese competition in Sugarcreek. The festival is the third and final of three contests whose total points determine the champion. Guggisberg has also won champion awards from fairs, shows, and festivals all over Ohio including the Ohio State Fair.

HOW THEIR CHEESE IS MADE

Local and surrounding Amish farmers send their milk to Guggisberg Cheese. The nutrients and minerals in the soil where the cows graze give their cheeses a distinctive flavor.

After the milk is weighed and tested, it’s cooled to a uniform temperature and stored in silos. Following pasteurization and clarifying (where the butterfat is standardized), it is then pumped into big copper vats. These vats can be seen through the viewing windows at the retail store.

At this stage, Guggisberg family recipes add the exact combinations of cultures, enzymes, and rennet to make cheese. Originally, rennet was extracted from calves stomachs. Now it comes from microbial fermentation. At Guggisberg Cheese, only the finest kosher rennet is used.

The enzymes, in combination with lactic acid produced by the cultures, causes the milk to thicken. In a half hour, its consistency resembles soft yogurt.

Cheese harps with razor sharp knives cut the mixture into 3/8 inch cubes called curds. These are then stirred and heated. During this warming process, cheese granules release a watery whey and become drier and smaller.

After reaching the right consistency, the curds and whey are pumped through pipes into a press vat. Much of the whey is drained off. The curd is then pressed into a large slab from which additional whey is drained.

The block is cut into smaller pieces which are placed in molds for 20 hours to make cheese wheels or loaves. During this process, the curd is turned several times to make sure the whey is drained out evenly on all sides.

The cheese is removed from the molds the next morning and placed into salt water brine for 24 hours. The brine is what forms the protective rind around the cheese’s outside. Afterwards, the cheese is dried and put into special bags. These bags release CO2 without letting in oxygen to enhance the aging process.

After packing, the cheese is taken into a warming room where secret cultures go to work. It’s here that bubbles form in the cheese’s weak spots. Different kinds of cheese age for different amounts of time depending upon the sharpness desired. For example, Baby Swiss stays in the maturing cellar for approximately four weeks. Premium Swiss cheese is aged for 60 days.

The cheese is ready to move to the cold cellar where it’s held for further aging or distribution for sale. Before sale, it has to be tasted and graded for its flavor, quality and eye formation. The two Guggisberg factories combine to make 80,000 pounds of cheese daily.

DETAILS

You will find Guggisberg Cheese at 5060 State Route 557 in Charm. Look for the Swiss bell tower which plays music every 15 minutes. Their telephone number is (800) 262-2505. Store hours are from November through March from Monday through Saturday 8:00 a.m. to 5:00 p.m. Closed on Sunday. From April through October, the hours are Monday through Saturday 8:00 a.m. to 6:00 p.m. and on Sunday from 11:00 a.m. to 4:00 p.m. They do offer a catalog and on line sales at their web site.

CHALET IN THE VALLEY RESTAURANT

On the opposite side of the road from the factory is Swiss Chalet Restaurant. Margaret Guggisberg’s passion was to own a restaurant serving Swiss and Austrian cuisine. Since she started it in 1983, diners have been treated to delicious meals featuring family recipes and champion cheeses. Built in the style of a Swiss chalet, the atmosphere is definitely Old World from the woodwork to servers wearing traditional Swiss dirndls. Visitors can watch goats playing outside.

Among their highlights are the bratwurst, fondues, and six different kinds of schnitzels. Premium Swiss Cheese is part of many of their sandwiches while Baby Swiss unexpectedly tops other dishes such as spaghetti. A soup and salad bar is available daily. On Fridays, diners enjoy an all-you-can-eat Pollock ($12.59) or perch ($12.99) while on Sundays, they savor a Hot Sunday buffet priced at $15.99. Dessert classics include strudel, Black Forest cake, date nut pudding and apple dumplings. Prices are moderate.

The restaurant is found at 5060 State Route 557 near Charm. Their telephone number is (330) 893-2550. They are closed mid December through February. On Sundays, the rest of the year, the hours are 11:00 a.m. to 3:00 p.m. From March through October, the hours Monday through Saturday are 11:00 a.m. to 8:00 p.m. From November through mid December, they open at 11:00 a.m. Tuesdays through Thursdays and close at 7:00 p.m. On Fridays and Saturdays, during that period, it’s 8:00 p.m. They are always closed on Mondays.

WENDELL AUGUST FORGE

With hammers and chisels as the only tools and a high degree of craftsmanship, Wendell August Forge artisans have delighted customers since 1923 making functional and decorative metalware.

Although their flagship store is near Mercer, Pennsylvania, a trip to their gift shop in Berlin, Ohio reveals hundreds of products in a wide variety of designs, shapes, and prices ranging from $10 up. It has become the place to shop in Northeast Ohio for handcrafted gifts for all occasions. The gifts are so unique that many have become family heirlooms.

A LITTLE HISTORY

Wendell August, a coal company broker, founded the company in Brockway, Pennsylvania. He hired Otto Pisoni, a blacksmith in his mine, to hand-forge wrought iron door latches for August’s new home that matched those at the entrance. Pisoni was to make duplicates since the originals were hard to match. He quickly captured the latches’ artistry for a fraction of the original cost. This led August to seeing the potential for creating artistic hand wrought ironware.

From this experience, the firm of Wendell August Forge was born. August hired Pisoni and three other blacksmiths in the 1920s to produce his first handcrafted wrought iron line which included fireplace andirons, door and window grilles, candlesticks, doorknockers, latches, and railings.

In the late 1920's, the Aluminum Company of America (ALCOA) was looking for alternative uses for aluminum. They held a nationwide search to create decorative aluminum gates for their research facility in New Kensington, Pennsylvania. Wendell August’s company had not worked in aluminum but entered the competition. Impressed with the products Alcoa’s management saw, such as a large wrought iron calling card, they hired Wendell August Forge to make gates and other creative uses of aluminum. This incident pioneered hand forged aluminum.

To thank Alcoa, Wendell August made hand hammered trays for several of their executives. One of those trays caught the eye of Edgar J. Kaufman of Kaufman Department Stores who had a home in Pittsburgh and liked to entertain. Kaufman asked August to make a tray or a plate with a picture of Kaufman’s home on it to give to his guests. August said, “Yes” although he had never done the process before. Kaufman commissioned the die and several plates.

Wendell August went back and with one of his blacksmiths came up with the idea of hand engraving a die in reverse using a hammer and chisel. To date, that is the process the company still uses to create their dies. The Kaufman die and the popularity of the trays handed out to Alcoa executives launched Wendell August’s giftware business.

Otto Pisoni, his blacksmith, became an expert at forging aluminum. The company also incorporated the designs of James McCausland, Wendell August’s designer and operations manager, who joined the company in 1928.

The early days of the Depression hit August hard and he lost everything except for the blacksmith shop. He advised his employees that they would be paid when the company was paid. It took six months for them to receive checks, but the forge doors remained open for business.

After this period, the forge received a contract to remodel the Grove City National Bank. The bank president offered to finance a new facility if August would move his company to Grove City, Pennsylvania. The move occurred in 1932. Once in the facility, the gift line was expanded and stores from Chicago to New York soon carried his products.

Aluminum supplies were diverted during World War II to the war effort. With the shortage of supplies, this caused the forge to close. Across town, employees opened a small shop called Pine Grove, creating pieces that were pressed rather than hand hammered. With the war’s end, aluminum became available to private industry and the forge reopened.

During the 1940's, Wendell was joined by his son Robert. Sales for Wendell August soared as their product lines expanded. The popularity of aluminum giftware grew. Hand hammered tray and serving pieces started becoming collectors’ items.

In 1978, Bill Knecht III, of Youngstown, Ohio acquired the company from Wendell’s son, Robert August. He operated the company until his death in 2004. His son, Will Knecht, runs the firm today.

The original Grove City store burned to the ground in March of 2010. Twenty fire teams could not extinguish the blaze. It had been on the National Registry of Historic Places. It was not only the oldest and largest forge in the States but a retail store that housed the administrative and executive offices. Fortunately, fire fighters were able to save more than 3,000 dies.

Two days before, Wendell August had received their largest order ever. It was from the Pittsburgh Penguins. They were to transform metal sheets from the demolished roof of the old Civic Arena into Pittsburgh Penguin mementos. This concentrated their efforts as the company knew they had to accomplish the contract since the Penguins were playing their last NHL (national hockey league) game in their historic arena.

Rather than the firm folding, they opened up a temporary workshop five days after the fire. Within two weeks, they had executive offices and within four weeks a new temporary retail store. They fulfilled the Pittsburgh Penguins order.

A new permanent facility, near Mercer, Pennsylvania, opened in October of 2013. At 52,000 square feet, it nearly doubled their floor space. Acting as their flagship, it's also their history center, provides self-guided workshop tours, and sells their many products. Its location is 2074 Leesburg-Grove City Road. A second store is in the middle of Amish country in Berlin, Ohio.

They also make awards, commemoratives, trophies, and corporate gifts. In addition to the company’s retail stores, Wendell August sells its products through its own catalog and online.

THE BERLIN, OHIO STORE

At this store, many products are displayed in a number of Amish Country and floral designs. Best sellers are Christmas ornaments and coasters. You’ll also see plates, wedding gifts, baby gifts, serving pieces, and home accessories. Engraving is offered. A section is devoted to hand-crafted jewelry. This includes rings, earrings, and necklaces.

Besides the huge selection of unique, handcrafted, metal giftware, you’ll find the world’s largest Amish buggy. It was made for the company by a local Amishman. It stands more than 10 feet high, has 5-foot tall wheels, and weighs in at 1,200 pounds.

They have a video on the company’s history which portrays how their products are crafted. A small museum displays giftware from the 1920s through the 1950s. In the rear room, walk through their fully functional forge where tools from engraving dies to product creation are set up.

While it’s Mercer, Pennsylvania where the main forge is located, sometimes craftsmen appear at the Berlin store to demonstrate the process. From early August to mid November, on Fridays and Saturdays, from 9:00 a.m. to 4:00 p.m. you can meet these artisans and watch them make gifts. You can also immerse yourself in a hand hammering experience to make your own treasure.

HOW IS A TRAY MADE

We were fortunate to watch trays being made in Berlin. Don Polding did the hammering while Nunzio Bartolne demonstrated the rest of the process.

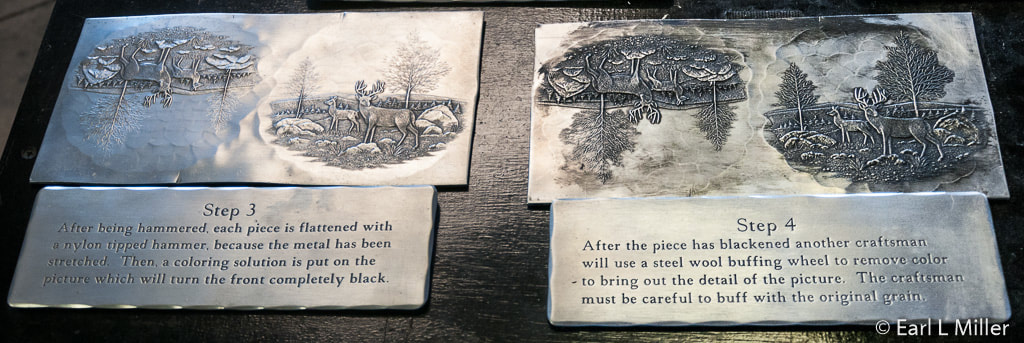

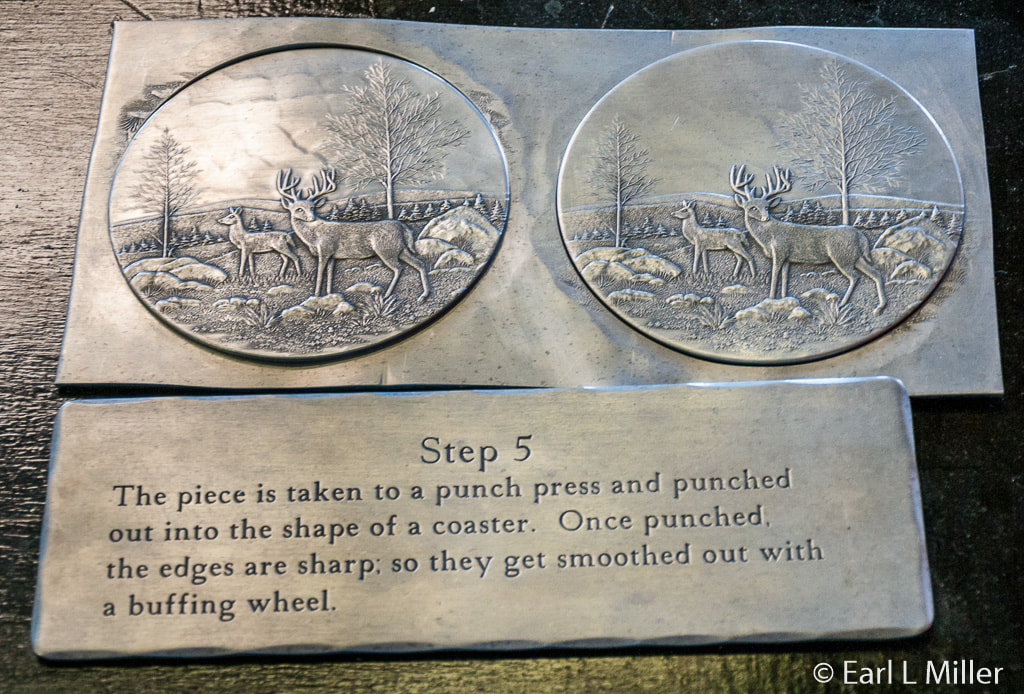

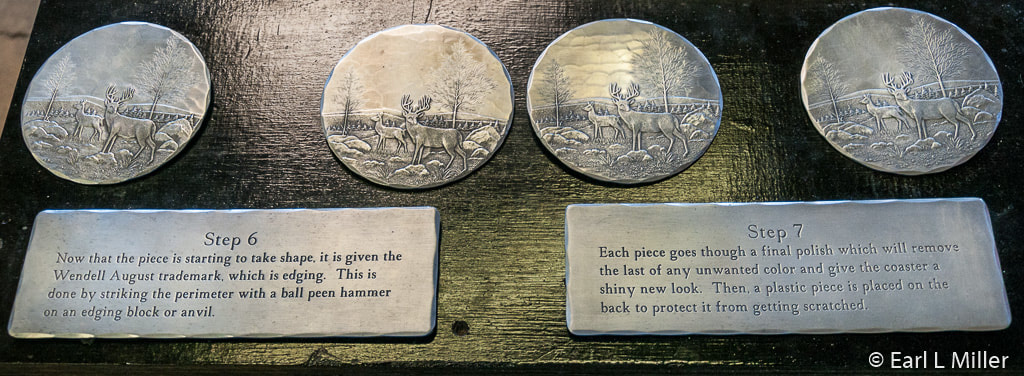

The multi step process starts with die engraving by a master engraver. It continues with material selection, cutting, and hammering. The process concludes with edging, carbon coloring or coal firing, polishing, and forming.

While craftsmen create new motifs and designs each year, some like the dogwood have lasted for decades. Others have been retired. All are unique and handcrafted in America. No two products are the same.

New designs come from free lance artists. Their custom idea is mapped out, and the artwork for it is created. It may take as much as ten weeks.

Master die engravers then create the artist’s design into a steel die in reverse mirror image using a hammer and chisels. This die is used to make an engraver’s proof so changes can be made as necessary. Usually, a couple of proofs are made. Since each die is unique in artistry and craftsmanship, the engraver hides his initials in the design, similar to all great artists who sign their artwork.

Plain sheets of metal - aluminum, pewter, bronze, and copper are cut into a smaller pieces and prepared to be jack hammered into a specific item. To cut the metal, with trays, they use a shears cutter. However, with big plates and coasters, a circle cutter is used. Nunzio advised us that this takes about five or ten minutes.

Buffer wheels get rid of the burr. The craftsmen have different wheels with different grit that is similar to sandpaper.

After the metal is clamped down, it’s jack hammered on top of the die to create a mirror image of the artwork on the metal. When finished, the craftsman affixes the company hallmark and his personal touch mark. The craftsman applies a symmetrical hand-hammered border all around the product providing a unique finished edge. This is a trademark of Wendell August.

Excess metal is removed off the edges and the piece trimmed to smooth down the sides. The piece is placed on a specially designed screen into a forge’s fireplace. This allows a precise amount of black smoke (color) to permeate the piece and be baked into it, enhancing the design and desired look of the piece.

When the piece cools, craftsmen who are expert finishers remove most of the color via a three step polishing process. They eliminate excess color, leaving just enough to highlight the design and achieve the right luster or patina. Steel wool and beeswax are used for polishing.

Some pieces are placed into molds where they’re pressed into unique forms such as trays or plates. This gives shape to the product.

CARE OF THE ITEMS

At Wendell August, all products are "food safe" from preparation to cleanup. However, there are precautions to take for the care of each piece.

Do not cut on any product since it can add a deep permanent gash to the metal. While you can place cookies and sandwiches on the piece, it’s wise to use a protector if you are serving cake with icing, cold cuts, and cheese. Wendell August sells these separately. An option is to use a piece of clear plastic wrap before placing food on it.

You can chill in the item but not cook in it and dishwasher usage is disallowed as well. Instead, your Wendell August products should be hand washed with a mild soap and water and dried immediately. Do not use the pieces as ashtrays.

Feel free to dust occasionally your aluminum piece with a soft cloth, going with the grain of the metal. The grains are the fine lines that go left to right on each piece. Aluminum and pewter darken with age. With aluminum, to remove discoloration and fingerprints and restore the luster, polish the piece with a non abrasive polishing cloth. Polishing pewter with steel wool brings back the sparkle. It is best to display pewter items by laying them flat or hanging them since they will warp because of the metal’s weight if laid on the resting edge.

Do not wash bronze and copper pieces including hand washing. These metals have a lacquer finish to retard tarnishing. Washing these pieces compromises the lacquer. Oily/acidic/moist properties of foods can also damage the lacquer. The only way to repair a tarnished product is to have it redone at Wendell August. They will restrip the lacquer, recolor, repolish, and relacquer the piece. Note that there are fees for refinishing.

DETAILS FOR BERLIN STORE

At 7007 County Road 672, off State Route 62, you come across Wendell August’s 13,000 square foot, timber frame facility which opened in 1994. The 5,000 foot showroom is open from Monday through Saturday from 9:00 a.m. to 6:00 p.m. but closed on Sunday. Their telephone number is (330) 893-3713.

MRS. YODER’S KITCHEN

On one of our trips to Amish country, we asked the manager at the Farm at Walnut Creek where do the Amish eat when they dine out. He strongly recommended Mrs. Yoder’s Kitchen found in Mt. Hope, Ohio. You can order off the menu, enjoy their lunch or dinner buffet, or have a family style meal.

Prices for ordering off the menu are in the $11.49 to $13.99 range. Their Friday buffet features fish, barbecue ribs, and popcorn shrimp. Lunch and dinner buffets cost $12.49. For children ages 6-10 it’s $9.99 and for ages 3-5 it’s $6.99. A breakfast buffet is offered Wednesday and Saturday from 7:00 to 10:30 a.m.

The family style meal incorporates a choice of one to three entrees. These are chicken, honey ham, roast beef, turkey, and Wedding steak. Prices range from $13.99 to $15.99 with dessert added for only $2.49. The meal includes mashed potatoes, dressing, vegetable, a salad bar, home style bread, and choice of a beverage.

You’ll find the restaurant at 8101 State Route 241, Mt. Hope, Ohio. Their telephone number is (330) 674-0922. Hours are 7:00 a.m. to 8:00 p.m. Monday through Saturday. Closed on Sunday.

FREE NOTIFICATION SERVICE

If you want to be notified of new articles, go to the Contact Form on this web site. To sign up, it’s required to provide your NAME, CITY, and STATE along with your request. Personal information and emails are never given out and there is no charge for this service.

Those traveling through Amish Country discover numerous restaurants and stores worth visiting. While at these places, take time to browse their brochure racks pointing you to additional places to explore throughout the area. Then take some of this information, read it, and check out what interests you.

Besides those mentioned in part one, here are other places we recommend. For prize winning cheese, stop at Guggisberg Cheese in Charm, Ohio. This company originated Baby Swiss cheese and has consistently won national and state awards for its premium Swiss. Its delightful restaurant, across the street, features Swiss/Austrian dishes and atmosphere. Wendell August is THE place to go for hand forged gifts. We asked the Amish and learned they often choose Mrs.Yoders Kitchen in Mount Hope when eating out.

GUGGISBERG CHEESE

Alfred Guggisberg, the founder of Guggisberg Cheese, was only 16 when he started studying the art of cheese making in Berne, Switzerland. To further his education, he attended the famous Swiss Federal “Molkereishulle” (cheese makers’ institute) then practiced his craft in Europe and Africa for many years. Upon his coming to Ohio in 1947, Amish farmers convinced him that Charm, located in Ohio’s Doughty Valley, was the place for him to practice his craft. He purchased Doughty Valley Cheese which evolved in 1950 into Guggisberg Cheese.

In the 1960's, his goal was to develop a new style of Swiss cheese that Americans would prefer. He had noticed the American palate differed from that of Europeans when it came to enjoying the strong taste of traditional Swiss cheese. His new cheese had smaller “eyes” (holes) and a creamier taste.

Alfred’s wife, Margaret, called it “Baby Swiss” after she saw a wheel of it next to the much larger wheel of traditional Emmental Swiss. Baby Swiss launched in 1968 when Margaret approached the local grocery store chain, Buehler’s, a company which remains a regular customer of this product. Competitors have imitated Baby Swiss but never duplicated it since they lack the family recipe.

Under Alfred’s son, Richard Guggisberg, current company president, it has become one of the larger manufacturers of Swiss cheese in the United States and one of the biggest cheese manufacturers of any type in Ohio. The company sells to retail and wholesale customers all over Europe and the United States.

The third family generation is now involved. At Guggisberg, we met Ursula, Alfred’s granddaughter, who is marketing coordinator for the company.

In 1995, Guggisberg opened a new plant in Sugarcreek, Ohio. That same year, the Doughty Valley factory was remodeled and old equipment replaced with state-of-the-art technology. Sugarcreek's plant, specializing in the production of 200 pound blocks of traditional cheese, produces a much higher volume than Doughty Valley’s factor but isn't open to the public.

Guggisberg sells more than 60 varieties of cheese which you can sample at their gift shop. Their biggest seller is Baby Swiss. Amish butter cheese is similar to a Haverti since it is high in butter fat and very creamy. Lacerne, another type of Baby Swiss, is low in fat and sodium. Farmers Cheese is made partly from skim milk, has the texture of mozzarella, and the smooth finish of Swiss. Guggisberg also sells Swiss lace cheese and Emmental Swiss cheese.

To go along with several cases of cheese, you’ll find in their gift shop such meats as summer sausage and bologna; complements such as crackers, mustards, jams, and fudge; and cheese knives and spreaders. The shop also carries Amish and Swiss themed goods. Travelers will find everything from cuckoo clocks to Swiss chocolates.

THEIR AWARDS

Guggisberg has won numerous awards over the years. In 2017, it received first place at the U.S. Companionship Cheese Contest for premium Swiss and second place in that contest for Baby Swiss. It also won first place for its cheese in the Ohio Dairy contest.

In 2016, Guggisberg received first place in the World Championship Cheese Contest for premium Swiss. Hosted by the Wisconsin Cheese makers Association, it alternates every other year with the United States Cheese Championship. It’s the world’s largest technical cheese, butter, and yogurt competition. The 2016 competition had 2,948 submissions from 23 countries. Guggisberg also took second, fourth, and fifth place with additional entries in the Swiss style category.

During 2015, the company received numerous awards. This included being United States Grand Champion at the United States Cheese Championship with entries from 28 states. More than 33,000 pounds of dairy products were entered into the contest which dates back to 1891 by the Wisconsin Cheese Makers Association. It’s one of the country’s most prestigious competitions.

In 2016, Guggisberg also won Ohio Grand Champion Cheese maker for premium Swiss. In the 2015 American Cheese Society contest, it won first place for Baby Swiss and colby and second place for Emmental Swiss. It was awarded third place in the U.S. Cheese Championship for colby.

In addition, Guggisberg has been awarded Ohio Swiss Cheese Association’s Grand Champion Cheese maker from 2011 through 2016 at the Ohio Swiss Festival’s cheese competition in Sugarcreek. The festival is the third and final of three contests whose total points determine the champion. Guggisberg has also won champion awards from fairs, shows, and festivals all over Ohio including the Ohio State Fair.

HOW THEIR CHEESE IS MADE

Local and surrounding Amish farmers send their milk to Guggisberg Cheese. The nutrients and minerals in the soil where the cows graze give their cheeses a distinctive flavor.

After the milk is weighed and tested, it’s cooled to a uniform temperature and stored in silos. Following pasteurization and clarifying (where the butterfat is standardized), it is then pumped into big copper vats. These vats can be seen through the viewing windows at the retail store.

At this stage, Guggisberg family recipes add the exact combinations of cultures, enzymes, and rennet to make cheese. Originally, rennet was extracted from calves stomachs. Now it comes from microbial fermentation. At Guggisberg Cheese, only the finest kosher rennet is used.

The enzymes, in combination with lactic acid produced by the cultures, causes the milk to thicken. In a half hour, its consistency resembles soft yogurt.

Cheese harps with razor sharp knives cut the mixture into 3/8 inch cubes called curds. These are then stirred and heated. During this warming process, cheese granules release a watery whey and become drier and smaller.

After reaching the right consistency, the curds and whey are pumped through pipes into a press vat. Much of the whey is drained off. The curd is then pressed into a large slab from which additional whey is drained.

The block is cut into smaller pieces which are placed in molds for 20 hours to make cheese wheels or loaves. During this process, the curd is turned several times to make sure the whey is drained out evenly on all sides.

The cheese is removed from the molds the next morning and placed into salt water brine for 24 hours. The brine is what forms the protective rind around the cheese’s outside. Afterwards, the cheese is dried and put into special bags. These bags release CO2 without letting in oxygen to enhance the aging process.

After packing, the cheese is taken into a warming room where secret cultures go to work. It’s here that bubbles form in the cheese’s weak spots. Different kinds of cheese age for different amounts of time depending upon the sharpness desired. For example, Baby Swiss stays in the maturing cellar for approximately four weeks. Premium Swiss cheese is aged for 60 days.

The cheese is ready to move to the cold cellar where it’s held for further aging or distribution for sale. Before sale, it has to be tasted and graded for its flavor, quality and eye formation. The two Guggisberg factories combine to make 80,000 pounds of cheese daily.

DETAILS

You will find Guggisberg Cheese at 5060 State Route 557 in Charm. Look for the Swiss bell tower which plays music every 15 minutes. Their telephone number is (800) 262-2505. Store hours are from November through March from Monday through Saturday 8:00 a.m. to 5:00 p.m. Closed on Sunday. From April through October, the hours are Monday through Saturday 8:00 a.m. to 6:00 p.m. and on Sunday from 11:00 a.m. to 4:00 p.m. They do offer a catalog and on line sales at their web site.

CHALET IN THE VALLEY RESTAURANT

On the opposite side of the road from the factory is Swiss Chalet Restaurant. Margaret Guggisberg’s passion was to own a restaurant serving Swiss and Austrian cuisine. Since she started it in 1983, diners have been treated to delicious meals featuring family recipes and champion cheeses. Built in the style of a Swiss chalet, the atmosphere is definitely Old World from the woodwork to servers wearing traditional Swiss dirndls. Visitors can watch goats playing outside.

Among their highlights are the bratwurst, fondues, and six different kinds of schnitzels. Premium Swiss Cheese is part of many of their sandwiches while Baby Swiss unexpectedly tops other dishes such as spaghetti. A soup and salad bar is available daily. On Fridays, diners enjoy an all-you-can-eat Pollock ($12.59) or perch ($12.99) while on Sundays, they savor a Hot Sunday buffet priced at $15.99. Dessert classics include strudel, Black Forest cake, date nut pudding and apple dumplings. Prices are moderate.

The restaurant is found at 5060 State Route 557 near Charm. Their telephone number is (330) 893-2550. They are closed mid December through February. On Sundays, the rest of the year, the hours are 11:00 a.m. to 3:00 p.m. From March through October, the hours Monday through Saturday are 11:00 a.m. to 8:00 p.m. From November through mid December, they open at 11:00 a.m. Tuesdays through Thursdays and close at 7:00 p.m. On Fridays and Saturdays, during that period, it’s 8:00 p.m. They are always closed on Mondays.

WENDELL AUGUST FORGE

With hammers and chisels as the only tools and a high degree of craftsmanship, Wendell August Forge artisans have delighted customers since 1923 making functional and decorative metalware.

Although their flagship store is near Mercer, Pennsylvania, a trip to their gift shop in Berlin, Ohio reveals hundreds of products in a wide variety of designs, shapes, and prices ranging from $10 up. It has become the place to shop in Northeast Ohio for handcrafted gifts for all occasions. The gifts are so unique that many have become family heirlooms.

A LITTLE HISTORY

Wendell August, a coal company broker, founded the company in Brockway, Pennsylvania. He hired Otto Pisoni, a blacksmith in his mine, to hand-forge wrought iron door latches for August’s new home that matched those at the entrance. Pisoni was to make duplicates since the originals were hard to match. He quickly captured the latches’ artistry for a fraction of the original cost. This led August to seeing the potential for creating artistic hand wrought ironware.

From this experience, the firm of Wendell August Forge was born. August hired Pisoni and three other blacksmiths in the 1920s to produce his first handcrafted wrought iron line which included fireplace andirons, door and window grilles, candlesticks, doorknockers, latches, and railings.

In the late 1920's, the Aluminum Company of America (ALCOA) was looking for alternative uses for aluminum. They held a nationwide search to create decorative aluminum gates for their research facility in New Kensington, Pennsylvania. Wendell August’s company had not worked in aluminum but entered the competition. Impressed with the products Alcoa’s management saw, such as a large wrought iron calling card, they hired Wendell August Forge to make gates and other creative uses of aluminum. This incident pioneered hand forged aluminum.

To thank Alcoa, Wendell August made hand hammered trays for several of their executives. One of those trays caught the eye of Edgar J. Kaufman of Kaufman Department Stores who had a home in Pittsburgh and liked to entertain. Kaufman asked August to make a tray or a plate with a picture of Kaufman’s home on it to give to his guests. August said, “Yes” although he had never done the process before. Kaufman commissioned the die and several plates.

Wendell August went back and with one of his blacksmiths came up with the idea of hand engraving a die in reverse using a hammer and chisel. To date, that is the process the company still uses to create their dies. The Kaufman die and the popularity of the trays handed out to Alcoa executives launched Wendell August’s giftware business.

Otto Pisoni, his blacksmith, became an expert at forging aluminum. The company also incorporated the designs of James McCausland, Wendell August’s designer and operations manager, who joined the company in 1928.

The early days of the Depression hit August hard and he lost everything except for the blacksmith shop. He advised his employees that they would be paid when the company was paid. It took six months for them to receive checks, but the forge doors remained open for business.

After this period, the forge received a contract to remodel the Grove City National Bank. The bank president offered to finance a new facility if August would move his company to Grove City, Pennsylvania. The move occurred in 1932. Once in the facility, the gift line was expanded and stores from Chicago to New York soon carried his products.

Aluminum supplies were diverted during World War II to the war effort. With the shortage of supplies, this caused the forge to close. Across town, employees opened a small shop called Pine Grove, creating pieces that were pressed rather than hand hammered. With the war’s end, aluminum became available to private industry and the forge reopened.

During the 1940's, Wendell was joined by his son Robert. Sales for Wendell August soared as their product lines expanded. The popularity of aluminum giftware grew. Hand hammered tray and serving pieces started becoming collectors’ items.

In 1978, Bill Knecht III, of Youngstown, Ohio acquired the company from Wendell’s son, Robert August. He operated the company until his death in 2004. His son, Will Knecht, runs the firm today.

The original Grove City store burned to the ground in March of 2010. Twenty fire teams could not extinguish the blaze. It had been on the National Registry of Historic Places. It was not only the oldest and largest forge in the States but a retail store that housed the administrative and executive offices. Fortunately, fire fighters were able to save more than 3,000 dies.

Two days before, Wendell August had received their largest order ever. It was from the Pittsburgh Penguins. They were to transform metal sheets from the demolished roof of the old Civic Arena into Pittsburgh Penguin mementos. This concentrated their efforts as the company knew they had to accomplish the contract since the Penguins were playing their last NHL (national hockey league) game in their historic arena.

Rather than the firm folding, they opened up a temporary workshop five days after the fire. Within two weeks, they had executive offices and within four weeks a new temporary retail store. They fulfilled the Pittsburgh Penguins order.

A new permanent facility, near Mercer, Pennsylvania, opened in October of 2013. At 52,000 square feet, it nearly doubled their floor space. Acting as their flagship, it's also their history center, provides self-guided workshop tours, and sells their many products. Its location is 2074 Leesburg-Grove City Road. A second store is in the middle of Amish country in Berlin, Ohio.

They also make awards, commemoratives, trophies, and corporate gifts. In addition to the company’s retail stores, Wendell August sells its products through its own catalog and online.

THE BERLIN, OHIO STORE

At this store, many products are displayed in a number of Amish Country and floral designs. Best sellers are Christmas ornaments and coasters. You’ll also see plates, wedding gifts, baby gifts, serving pieces, and home accessories. Engraving is offered. A section is devoted to hand-crafted jewelry. This includes rings, earrings, and necklaces.

Besides the huge selection of unique, handcrafted, metal giftware, you’ll find the world’s largest Amish buggy. It was made for the company by a local Amishman. It stands more than 10 feet high, has 5-foot tall wheels, and weighs in at 1,200 pounds.

They have a video on the company’s history which portrays how their products are crafted. A small museum displays giftware from the 1920s through the 1950s. In the rear room, walk through their fully functional forge where tools from engraving dies to product creation are set up.

While it’s Mercer, Pennsylvania where the main forge is located, sometimes craftsmen appear at the Berlin store to demonstrate the process. From early August to mid November, on Fridays and Saturdays, from 9:00 a.m. to 4:00 p.m. you can meet these artisans and watch them make gifts. You can also immerse yourself in a hand hammering experience to make your own treasure.

HOW IS A TRAY MADE

We were fortunate to watch trays being made in Berlin. Don Polding did the hammering while Nunzio Bartolne demonstrated the rest of the process.

The multi step process starts with die engraving by a master engraver. It continues with material selection, cutting, and hammering. The process concludes with edging, carbon coloring or coal firing, polishing, and forming.

While craftsmen create new motifs and designs each year, some like the dogwood have lasted for decades. Others have been retired. All are unique and handcrafted in America. No two products are the same.

New designs come from free lance artists. Their custom idea is mapped out, and the artwork for it is created. It may take as much as ten weeks.

Master die engravers then create the artist’s design into a steel die in reverse mirror image using a hammer and chisels. This die is used to make an engraver’s proof so changes can be made as necessary. Usually, a couple of proofs are made. Since each die is unique in artistry and craftsmanship, the engraver hides his initials in the design, similar to all great artists who sign their artwork.

Plain sheets of metal - aluminum, pewter, bronze, and copper are cut into a smaller pieces and prepared to be jack hammered into a specific item. To cut the metal, with trays, they use a shears cutter. However, with big plates and coasters, a circle cutter is used. Nunzio advised us that this takes about five or ten minutes.

Buffer wheels get rid of the burr. The craftsmen have different wheels with different grit that is similar to sandpaper.

After the metal is clamped down, it’s jack hammered on top of the die to create a mirror image of the artwork on the metal. When finished, the craftsman affixes the company hallmark and his personal touch mark. The craftsman applies a symmetrical hand-hammered border all around the product providing a unique finished edge. This is a trademark of Wendell August.

Excess metal is removed off the edges and the piece trimmed to smooth down the sides. The piece is placed on a specially designed screen into a forge’s fireplace. This allows a precise amount of black smoke (color) to permeate the piece and be baked into it, enhancing the design and desired look of the piece.

When the piece cools, craftsmen who are expert finishers remove most of the color via a three step polishing process. They eliminate excess color, leaving just enough to highlight the design and achieve the right luster or patina. Steel wool and beeswax are used for polishing.

Some pieces are placed into molds where they’re pressed into unique forms such as trays or plates. This gives shape to the product.

CARE OF THE ITEMS

At Wendell August, all products are "food safe" from preparation to cleanup. However, there are precautions to take for the care of each piece.

Do not cut on any product since it can add a deep permanent gash to the metal. While you can place cookies and sandwiches on the piece, it’s wise to use a protector if you are serving cake with icing, cold cuts, and cheese. Wendell August sells these separately. An option is to use a piece of clear plastic wrap before placing food on it.

You can chill in the item but not cook in it and dishwasher usage is disallowed as well. Instead, your Wendell August products should be hand washed with a mild soap and water and dried immediately. Do not use the pieces as ashtrays.

Feel free to dust occasionally your aluminum piece with a soft cloth, going with the grain of the metal. The grains are the fine lines that go left to right on each piece. Aluminum and pewter darken with age. With aluminum, to remove discoloration and fingerprints and restore the luster, polish the piece with a non abrasive polishing cloth. Polishing pewter with steel wool brings back the sparkle. It is best to display pewter items by laying them flat or hanging them since they will warp because of the metal’s weight if laid on the resting edge.

Do not wash bronze and copper pieces including hand washing. These metals have a lacquer finish to retard tarnishing. Washing these pieces compromises the lacquer. Oily/acidic/moist properties of foods can also damage the lacquer. The only way to repair a tarnished product is to have it redone at Wendell August. They will restrip the lacquer, recolor, repolish, and relacquer the piece. Note that there are fees for refinishing.

DETAILS FOR BERLIN STORE

At 7007 County Road 672, off State Route 62, you come across Wendell August’s 13,000 square foot, timber frame facility which opened in 1994. The 5,000 foot showroom is open from Monday through Saturday from 9:00 a.m. to 6:00 p.m. but closed on Sunday. Their telephone number is (330) 893-3713.

MRS. YODER’S KITCHEN

On one of our trips to Amish country, we asked the manager at the Farm at Walnut Creek where do the Amish eat when they dine out. He strongly recommended Mrs. Yoder’s Kitchen found in Mt. Hope, Ohio. You can order off the menu, enjoy their lunch or dinner buffet, or have a family style meal.

Prices for ordering off the menu are in the $11.49 to $13.99 range. Their Friday buffet features fish, barbecue ribs, and popcorn shrimp. Lunch and dinner buffets cost $12.49. For children ages 6-10 it’s $9.99 and for ages 3-5 it’s $6.99. A breakfast buffet is offered Wednesday and Saturday from 7:00 to 10:30 a.m.

The family style meal incorporates a choice of one to three entrees. These are chicken, honey ham, roast beef, turkey, and Wedding steak. Prices range from $13.99 to $15.99 with dessert added for only $2.49. The meal includes mashed potatoes, dressing, vegetable, a salad bar, home style bread, and choice of a beverage.

You’ll find the restaurant at 8101 State Route 241, Mt. Hope, Ohio. Their telephone number is (330) 674-0922. Hours are 7:00 a.m. to 8:00 p.m. Monday through Saturday. Closed on Sunday.

FREE NOTIFICATION SERVICE

If you want to be notified of new articles, go to the Contact Form on this web site. To sign up, it’s required to provide your NAME, CITY, and STATE along with your request. Personal information and emails are never given out and there is no charge for this service.

Guggisberg Cheese, Doughty Valley Factory Near Charm

Lots of Their Swiss Cheese

Varieties of Other Guggisberg Cheese

Interior of the Guggisberg Cheese Store

Another View of the Store's Interior

Berlin Home of Wendell August

Interior View of Wendell August

A Better Look at Their Trays

Display of Their Coasters

World's Largest Amish Buggy

Different Metals Used Over the Years

Nunzio Bartolne Cutting Blanks for Coasters

Embossing the Edge

Shaping the Coaster

Don Polding Stamping on the Design

Description of Coloring the Design

How the Design is Punch Pressed

Description of Edging and Polishing

Completed Coasters with Hammered Edges

Closeups of Different Products

Closeups of Two Trays

Pineapple Plate

Light Switch Plates