Hello Everyone,

Because of windmills, Nebraska changed from being known as the “Great Desert” to becoming prime agricultural land. Since sufficient acreage was not always available near rivers and streams, these structures allowed farmers to pump ground water into dry areas so pioneers could homestead and successfully irrigate their crops.

Nebraska City, south of Omaha, is rich with agricultural attractions to explore. Kregel Windmill Factory Museum is a time capsule of an early 20th century manufacturing shop. Kimmel Orchard & Vineyard demonstrates what Nebraska’s agriculture is like today. At Arbor Lodge State Historical Park, walk the grounds and/or visit the 52-room home of the Morton family who started Arbor Day. In between, stop for lunch at Runza Drive Inn to dine on a true Nebraska sandwich. And that’s only a starter list.

NEBRASKA CITY TOURISM AND COMMERCE CENTER

With so much to see in this town, start your visit here by picking up brochures. Their friendly staff is an excellent source to answer questions and help you plan your entire stay from lodging to dining, attractions, and festivals. If you want to plan ahead of time, visit their web site. You’ll need a minimum of two to three days in Nebraska City to take in its top attractions. The Bureau’s address is 806 1st Avenue in Nebraska City. You can call them at (402) 873-6654.

KREGEL WINDMILL FACTORY MUSEUM

In 1879, two cousins, George and Louis Kregel started making wooden windmills in Nebraska City. They also produced wagons, buggies, and reapers. Their factory, the site of the current city hall, was across the street from where they permanently moved in 1903. Louis patented the two wooden style windmills the Kregel Windmill Company made.

Between 1903 and 1983, the company built 2,000 Eli metal windmills of which around 100 stand today. The vast majority were within 50 miles of Nebraska City in southeast Nebraska and into Iowa, Kansas, and Missouri. They were used on farms, ranches, and in towns.

The name Eli came from a Lutheran minister who worked in Nebraska City and Omaha, Eli Huber. He mentored George Kregel. It also had to do with marketing. The letters were bigger with Eli than Kregel. The name was also easier to remember.

Most were produced in the teens and 1920s with the peak year being 1923 when the company built 130. The depression decreased their business to only a few dozen made each year, and by 1939, the number was six. During World War II, because of metal rationing, Kregel stopped manufacturing windmills and concentrated on maintenance and repair. At that time, farmers had to apply to the government for a certificate proving they needed one. After the war, the company only made a few windmills each year with the last one produced in 1983.

After that year until they closed in 1991, the company focused on service and repair work on any kind of windmill, pumps, and well systems in a 40-mile radius around the town. The company also built water tanks and beehive boxes. Art, George’s son, was a member of the beekeeping association. At one time the area had 12 orchards, now three, so there was a market for beekeeping.

Besides being blacksmiths, each employee knew how to work all the stations in the factory including maintenance. The same six to eight employees would assemble the windmill on farms. Work was very difficult with poor lighting. The shop was very hot in the summer and very cold in the winter.

In 1944, Art took over the business for his father who died in 1946. He ran the company until 1991 when he went home one Friday afternoon. That weekend, he had a stroke and never returned. His sister Ella ran the Kregel office. She would talk to farmers through the front window so they wouldn’t drag mud into the factory. She died at her desk in 1971.

After Art’s death, for many years, the factory lay abandoned. The family turned the entire factory, including the tools, over to the Kimmel Foundation in Lincoln as well as Nebraska City’s Nelson Family Foundation and Wirth Foundation. Historical restoration, which started in 2010, took three years with the museum opening in 2013. Since the purpose was preservation, very little was moved or touched with artifacts left in their natural state. It is now run as a 501(c)(3) nonprofit museum.

WHAT YOU SEE

Kregel, the only windmill factory museum in the country, appears like a company frozen in time. Parts, tools on the work bench, equipment, and office supplies are original. It’s as if the workers left for lunch, disappeared, and never returned.

In the office, you can see Art’s jacket, an open safe, a telephone, and used pens and pencils laid out. You’ll even see his glasses and handkerchief. Oil in a pan, drained from a Dempster 712 windmill gearbox Kregel was trying to repair, awaits his return. His sister was typing a letter when she died of a heart attack. That letter is still in the manual typewriter with the last word unfinished.

Meticulous records of every sale, every customer, and every windmill made are in the office. It is considered to be one of the most complete collections in Nebraska for business records. They averaged two pages a day for 112 years, a total of 80,000 pages.

You can also see an early version of a printing machine. The Kregels made their own brochures which they would send to farmers. Their slogan was “Simplest and best made mill.”

The company made their own equipment. For example, they didn’t buy a floating table saw standard in most carpentry shops. They bought the saw’s pieces and built a wood structure around it.

In the forge area, employees melted down tin and a little bit of lead to make babbit to put in their bearings. When they were concentrating on servicing, they would rebabbit the windmill bearings. The forge was also used to heat up steel parts of windmills that needed to be pounded out or shaped into a particular piece they needed. A 180-pound anvil was used.

One of the most unique pieces of equipment is the line shaft that runs east to west across the factory. It is one of only 13 operable factory line shafts in its original place in the country and one of 28 in the world. Eighteen pieces of equipment could link to it, but only two or three pieces of machinery could run at one time. It was originally powered by a 14 horsepower Van Dusen gas engine. When they stopped making that engine in 1919, it was replaced with two electrical motors. Pieces of equipment were turned on and off with shifter levers connected to the pulleys constructed of wood and metal. The shaft’s belts were made of buffalo hide so they were very strong.

Outside you can still see the 1903 outhouse. It hasn’t been removed as the building is on the National Historical Registry.

HOW THE WINDMILL WAS MADE

In the assembly area, you can see the head of an Eli windmill on a stub tower and learn how windmills were made on the original equipment. The Eli was an unusual design. It had no gears or any type of gear reduction. Instead it had a direct stroke, self-oiling design, and a ball-bearing swivel. Every time the Eli wheel turned, it pumped water. Its head locked in place during high winds. It was very simple to lubricate requiring only a cup of oil every three to six months. That was the only maintenance required. In the 1930s, it sold for $130. Some sold, just for the wheel, for $17.25.

In the windmill head assembly section, a sheet of galvanized steel was placed in an actuated cutter in order to cut blanks for the blades. Each blade was run through a roller to make the blade concave. This made it 87% more efficient than a wooden windmill. Making it of metal had other advantages. It was not as expensive and required less oil and paint.

The curved blade would be run through a crimper which made a double crimp on the blade’s tip, providing it with additional strength so it wouldn’t bend. An indentation in the shape of a dimple was put in. This step was necessary so that the outer rim piece would fit against the blade. The final machine riveted the inner and outer rim pieces to the windmill’s blades which completed the windmill’s head.

Windmills were built in sections with six blades to a section. Different size windmills had different size blades which varied the cost. A ten-foot windmill had 36 blades while an 8-1/2 foot windmill had 30 blades. Seventy-five percent of the windmills built were ten feet.

For the tower, the sheer punch called an iron worker, originally used in the shipping industry, was built around 1875. It took two people to operate. It enabled workers to cut heavy pieces of metal for the tower and also punch holes in the tower more quickly and accurately. To operate the punch, the employee would lift up the floor board revealing a bench seat where he would sit. He would then feed pieces into the punch via a lever on the side of the machine.

A turret lathe is the factory’s oldest piece of equipment, circa 1860, from Chicopee, Massachusetts. It would allow the worker to perform multiple tasks without having to reset the equipment. A spindle drill press allowed four different sizes of drill bits at one time. This saved time as the different drill bits didn’t have to be changed constantly.

It took about a week to assemble the windmill. Variables included the distance to the farm, height of the tower, and size of the wheel. Most tower sizes were 30 feet but some were 60 feet. Employees would complete the head, bring it to the farm, and assemble the windmill. It was then raised.The process was first done with horses and later by service trucks.

VISIBLE WINDMILL

Across the street from the museum, you’ll see a 35-foot, all steel Eli windmill that was produced in the 1920s. It has a ten-foot wheel and a 30-foot tower.

DETAILS

Kregel Windmill Factory Museum is located at 1416 Central Avenue in Nebraska City. Their telephone number is (402) 873-1078. Hours are closed Monday, Tuesday through Saturday 10:00 a.m. to 5:00 p.m., and on Sunday from 1:00 to 5:00 p.m. Admission is adults $8, students $5, children ages four and under are free. AAA/AARP/Veterans have a $1 discount. You can ask for a tour or take a self guided tour with the help of seven state of the art touch screens which explain the equipment and what you are seeing.

KIMMEL ORCHARD AND VINEYARD

If you want to learn about modern agriculture, head for Kimmel Orchard and Vineyard. It’s the place to pick your own produce, wander along trails, shop their store, take a hayrack ride, learn about apple production, or attend a festival.

Richard Kimmel grew up in Nebraska City. In 1925, he quit his job as a bank teller at Otoe National Bank in Nebraska City before establishing Kimmel Orchard. He also managed Kimmel Farms, established in the 1850s by his grandfather. His wife Laurine grew up with the Kimmels as neighbors. They married soon after he started the orchard. Their mission was to share the apples, tart cherries, and grapes they produced with their neighbors. While working together to build Kimmel Orchard, Laurine, who studied art at the University of Nebraska, became known nationally for her series of water color paintings titled “American Architecture.” They depicted old outhouses.

A German POW camp, located 30 miles away at Weeping Water, Nebraska, supplied the Orchard’s workers. Bill Oberdick, a German POW, was boss. He was caught defecting from Rommel. All of the POWs went back to Germany after the war except for Oberdick, who stayed on as the Orchard’s overseer. When Kimmel retired in 1967, he sold the orchard to Oberdick, who ran it for a number of years. When Oberdick retired, he sold it to his son-in-law, who, in turn, sold it to the Kimmel Foundation. The Orchard was renovated in 2000/2001.

Today the Orchard’s missions are agricultural educational research, historic preservation of the region’s orchard industry, and wholesome family experiences. The mission is to teach where food comes from and how important the fruit industry has been and continues to be in Nebraska.

In 2005, the Orchard built the Kimmel Education & Research Center in partnership with the University of Nebraska-Lincoln. The center houses research facilities, a food laboratory, meeting rooms, and offices. The university provides educational programs and helps partner events.

The orchard consists of 115 acres, 40 of which are in apple trees and eight in grapes. However, it also grows asparagus, strawberries, blackberries, Asian and regular pears, tart cherries, peaches, pumpkins, and gourds. Ninety percent of the produce is sold at the Orchard.

The Orchard traditionally grew 180 apple trees per acre with 15 feet between trees and 20 feet between the rows. Now they are mainly planting trees on dwarf root stock attached to trellises at 1,000 trees per acre. There are currently three feet between trees and 10-12 feet between rows. This has increased the yield per acre as compared to the older production. Under both methods, fruit is picked by hand.

U-PICK

Families are invited to explore the fields at leisure to pick fruits and vegetables from their source. U-Pick activities are seasonally dependent upon what is ripe with fruits and vegetables having different growing seasons.

The Orchard specializes in apples with 21 different varieties having harvesting dates from mid August through October. Each of the apples has their own characteristics when it comes to taste, color, and use such as eating or baking.

Apples vary in size because of the different species. At the Orchard, Lunchbox apples, less than two inches in diameter, are used for cider. The rest are sorted according to weight and size then hand inspected and graded. The machine is totally automatic, kicking out the bad apples with any defects. The best go for retail sale while the remainder are used for Kimmel pies and cider.

To make cider, the apples go through a grinder after they are washed. This resembles an applesauce which is pressed to extract all of the juices. The juice is filtered and purified then bottled, capped, and labeled. The rest (the pumice) is recycled.

OTHER PRODUCE

Markers at the end of rows help visitors identify what the produce is and what is in bloom. The Orchard supplies picking bags, helps weigh the fruit you purchase, and even pits the cherries. To participate, go to the red-roofed barn just north of the main buildings.

How are cherries pitted? They are sized in a rotating drum. When they reach the drum’s top, steel spikes push through the cherry to remove the pit while retaining the rest of the cherry. Cherries are bagged and returned to visitors or made into the Orchard’s cherry wine and pies.

Here is the fruit picking schedule for the other produce. This is for U-Pick and Pre Picked.

Strawberries Late May-Early June

Cherries Late June-Early July

Peaches Mid July-August

Blackberries Late July-Mid August prepicked only

Asian Pears Early September U-pick only

Pumpkins October

To learn about the different varieties, go their web site.

U-Pick hours are Saturday 9:00 a.m. to 4:00 p.m. and Sunday 11:00 a.m. to 4:00 p.m. in season. Admission prices for this activity are adults, 13 and older, $5; kids, ages 4 to 12, $3; seniors, 62 and older, $3; and military, active or retired, $3. Produce pricing is dependent on season and yield like the typical grocery store. It is purchased by the pound.

HAYRACK RIDES

These rides are included with your U-Pick/tree dome trail or event/festival admission and are available Saturdays and Sundays in September, October, and November. Your family can have a guided hayrack ride upon request. You’ll sit on hay bales as a farm tractor pulls the wagon on your tour.

NATURE TRAIL AND PLAYGROUND

The 1-1/2 mile interactive Tree Dome Nature Trail has informative signage and activities for children. Entrance to the trail is included in the U-Pick Admission. Along it, you will find Nebraska’s native plants. Be sure to notice the 170-year-old Eastern Cottonwood tree. You’ll also see animal track displays with corresponding animal descriptions, birdhouses, and waterfowl nests. The Orchard promotes wildlife observation from a young age.

The riparian area is home to lots of wildlife such as foxes, snapping turtles, deer, beavers, blue herons, geese, and wood ducks. At the pond, children can collect water samples to take to the research facility to check out microorganisms under microscopes firsthand.

Youngsters will also enjoy the Pollinator Playground consisting of two areas. One is for children ages 2 to 5 while the second is for youngsters ages 5 to 12. They’ll find a windmill slide and a child-sized Kimmel fruit stand.

THE APPLE BARN MARKET

The Market is known for its apple cider, apple doughnuts, and home-grown produce. However, lots of other products are also available. You can purchase dressings, homemade fudge, a variety of canned olives and canned vegetables, salsas, jams, jellies, pies, and popcorn. If that isn’t enough, they also have barbecue sauces, honey, syrups, and pre made mixes. It is closed January and February for maintenance. For details on their products, check out their web site.

Since the early 18th century, the area has grown premium grapes. The Orchard has been part of that scene since 1925 with six varieties of grapes. They offer fruit and grape wines which are made for them by Whiskey Run Creek Winery. Fresh pour sampling is only $5 for four selections, and you can keep the wine glass as a souvenir. See their site for information on wines.

FESTIVALS

The Orchard’s biggest festival is the Applejack Festival taking place September 20-22. The Apple Barn will be stocked with such treats as apple donuts, fresh cider, caramel apples, and apple pies. It will include live music, wine tastings, BBQ, face painting, and vendors. The Kimmel Education & Research Center will feature fun and educational activities for all ages. Other festivals are held throughout the year. For more information, visit their festival page.

TOURS

Individuals who want to learn about apple processing first hand can take a 30-minute tour which includes a showing of the apple sorting machine and cider production while providing an overview of the business and history of the facility. Processing takes place next to the café. The fee is five dollars.

DETAILS

Kimmel Orchard is located at 5995 G Rd, Nebraska City, Nebraska. Their telephone number is (402) 873-5293. Seasonal hours are March 1–December 23 Monday through Saturday: 9:00 a.m. to 5:00 p.m. and Sunday: 11 a.m. to 5 p.m. They do have an admission, as mentioned above, for U-Pick and the Tree Dome Nature Trail.

ARBOR DAY STATE HISTORICAL PARK

Due to a time shortage, we drove over to but did not tour the mansion owned by the founder of Arbor Day, J. Sterling Morton. From its beginnings as a four-room cabin in 1855, Morton expanded it to 30 rooms. His son Joy, president of Morton Salt Company in Chicago, grew it into a 52-room mansion that is a lookalike of the White House. Rooms house period as well as historical artifacts belonging to the Morton family.

The 72-acre park also includes an arboretum, an Italian terraced garden, a log cabin, a carriage house, walking trail, formal rose garden, and more than 200 varieties of lilacs. The log house is a memorial to the community’s settlers. A one-half mile tree trail winds through the original arboretum planted by the Mortons in the late 19th and early 20th centuries. The collection of trees and shrubs consist of more than 260 species including some that are native and some that are uncommon to the region. Many are labeled. The family gave the grounds to the Nebraska Game and Parks Commission in 1923. Grounds are open year round.

Picnicking is permitted in the area. Cider pressing and other old-time crafts take place the last two Sunday afternoons of September and the first two Sundays in October.

IT STARTED WITH TREES

Julius Sterling Morton, the founder of Arbor Day, was born in 1832 in Adams, New York. After obtaining his degree at the University of Michigan, he married his bride Caroline. They left for Nebraska the day they were married, settling in Nebraska City. He became the editor of the Nebraska News.

Morton was appointed Nebraska’s territorial Secretary of State from 1858 to 1861 by President James Buchanan and also served as the Acting Territorial Governor of Nebraska from 1858 to 1859. President Grover Cleveland appointed him as United States Secretary of Agriculture from 1893 to 1897. He supported Cleveland in setting up forest reservations.

At his home, Morton planted many rare varieties and heirloom apple trees. He instructed people in modern farming and forestry techniques. He believed trees would be effective windbreaks, protecting crops from erosion and overexposure to the sun. They would also provide fuel and building supplies. Morton promoted Arbor Day as a holiday to encourage the planting of trees.

He died in 1902. Nebraska donated a bronze statue of Morton to the National Statuary Hall Collection at the United States Capitol.

In 1872, the Nebraska State Board of Agriculture adopted Morton’s resolution to create Arbor Day. The first Arbor Day celebration occurred April 10, 1872 when more than a million trees were planted. During the 1880s, schools participated on Arbor Day by planting trees as memorials of historical events and to honor famous people. The state made it into a legal holiday in 1885. All other states, except Delaware, celebrated it within 20 years. Delaware eventually caved. Under Richard Nixon, it became a federal holiday on the last Friday in April. Alaska and Hawaii disregard the date since their planting schedules are a little different from the rest of the nation.

DETAILS

The park is located at 2611 Arbor Avenue, Nebraska City. The phone number is (402) 873-8717. Admission is adults $8, children ages 3-12 $6, children ages two and under free. Hours are Monday through Saturday 9:00 a.m. to 5:00 p.m. and on Sunday from 11:00 a.m. to 5:00 p.m.

RUNZA

If you are looking for a true Nebraska sandwich, head to Runza Drive Inn. Some commentators call it as Nebraskan as Cornhusker football. It is composed of a yeast dough bread pocket with a filling of beef, cabbage or sauerkraut, onions, and seasonings. They’re baked in various shapes ranging from a rectangle, a round, a square, to a triangle. The ones sold by Runza Drive Inn are rectangular. It is said to originate from a pierogi, a European dish of filled dumplings.

Not into a runza? The drive inn also sells hamburgers, french fries, onion rings, chili, salads, chicken strips, and cinnamon rolls. As of 2018, there are 85 Runza restaurants with 80 in Nebraska, two in Iowa, two in Kansas, and one in Colorado. You can find a Runza in Nebraska City at 702 S. 11th Street.

Because of windmills, Nebraska changed from being known as the “Great Desert” to becoming prime agricultural land. Since sufficient acreage was not always available near rivers and streams, these structures allowed farmers to pump ground water into dry areas so pioneers could homestead and successfully irrigate their crops.

Nebraska City, south of Omaha, is rich with agricultural attractions to explore. Kregel Windmill Factory Museum is a time capsule of an early 20th century manufacturing shop. Kimmel Orchard & Vineyard demonstrates what Nebraska’s agriculture is like today. At Arbor Lodge State Historical Park, walk the grounds and/or visit the 52-room home of the Morton family who started Arbor Day. In between, stop for lunch at Runza Drive Inn to dine on a true Nebraska sandwich. And that’s only a starter list.

NEBRASKA CITY TOURISM AND COMMERCE CENTER

With so much to see in this town, start your visit here by picking up brochures. Their friendly staff is an excellent source to answer questions and help you plan your entire stay from lodging to dining, attractions, and festivals. If you want to plan ahead of time, visit their web site. You’ll need a minimum of two to three days in Nebraska City to take in its top attractions. The Bureau’s address is 806 1st Avenue in Nebraska City. You can call them at (402) 873-6654.

KREGEL WINDMILL FACTORY MUSEUM

In 1879, two cousins, George and Louis Kregel started making wooden windmills in Nebraska City. They also produced wagons, buggies, and reapers. Their factory, the site of the current city hall, was across the street from where they permanently moved in 1903. Louis patented the two wooden style windmills the Kregel Windmill Company made.

Between 1903 and 1983, the company built 2,000 Eli metal windmills of which around 100 stand today. The vast majority were within 50 miles of Nebraska City in southeast Nebraska and into Iowa, Kansas, and Missouri. They were used on farms, ranches, and in towns.

The name Eli came from a Lutheran minister who worked in Nebraska City and Omaha, Eli Huber. He mentored George Kregel. It also had to do with marketing. The letters were bigger with Eli than Kregel. The name was also easier to remember.

Most were produced in the teens and 1920s with the peak year being 1923 when the company built 130. The depression decreased their business to only a few dozen made each year, and by 1939, the number was six. During World War II, because of metal rationing, Kregel stopped manufacturing windmills and concentrated on maintenance and repair. At that time, farmers had to apply to the government for a certificate proving they needed one. After the war, the company only made a few windmills each year with the last one produced in 1983.

After that year until they closed in 1991, the company focused on service and repair work on any kind of windmill, pumps, and well systems in a 40-mile radius around the town. The company also built water tanks and beehive boxes. Art, George’s son, was a member of the beekeeping association. At one time the area had 12 orchards, now three, so there was a market for beekeeping.

Besides being blacksmiths, each employee knew how to work all the stations in the factory including maintenance. The same six to eight employees would assemble the windmill on farms. Work was very difficult with poor lighting. The shop was very hot in the summer and very cold in the winter.

In 1944, Art took over the business for his father who died in 1946. He ran the company until 1991 when he went home one Friday afternoon. That weekend, he had a stroke and never returned. His sister Ella ran the Kregel office. She would talk to farmers through the front window so they wouldn’t drag mud into the factory. She died at her desk in 1971.

After Art’s death, for many years, the factory lay abandoned. The family turned the entire factory, including the tools, over to the Kimmel Foundation in Lincoln as well as Nebraska City’s Nelson Family Foundation and Wirth Foundation. Historical restoration, which started in 2010, took three years with the museum opening in 2013. Since the purpose was preservation, very little was moved or touched with artifacts left in their natural state. It is now run as a 501(c)(3) nonprofit museum.

WHAT YOU SEE

Kregel, the only windmill factory museum in the country, appears like a company frozen in time. Parts, tools on the work bench, equipment, and office supplies are original. It’s as if the workers left for lunch, disappeared, and never returned.

In the office, you can see Art’s jacket, an open safe, a telephone, and used pens and pencils laid out. You’ll even see his glasses and handkerchief. Oil in a pan, drained from a Dempster 712 windmill gearbox Kregel was trying to repair, awaits his return. His sister was typing a letter when she died of a heart attack. That letter is still in the manual typewriter with the last word unfinished.

Meticulous records of every sale, every customer, and every windmill made are in the office. It is considered to be one of the most complete collections in Nebraska for business records. They averaged two pages a day for 112 years, a total of 80,000 pages.

You can also see an early version of a printing machine. The Kregels made their own brochures which they would send to farmers. Their slogan was “Simplest and best made mill.”

The company made their own equipment. For example, they didn’t buy a floating table saw standard in most carpentry shops. They bought the saw’s pieces and built a wood structure around it.

In the forge area, employees melted down tin and a little bit of lead to make babbit to put in their bearings. When they were concentrating on servicing, they would rebabbit the windmill bearings. The forge was also used to heat up steel parts of windmills that needed to be pounded out or shaped into a particular piece they needed. A 180-pound anvil was used.

One of the most unique pieces of equipment is the line shaft that runs east to west across the factory. It is one of only 13 operable factory line shafts in its original place in the country and one of 28 in the world. Eighteen pieces of equipment could link to it, but only two or three pieces of machinery could run at one time. It was originally powered by a 14 horsepower Van Dusen gas engine. When they stopped making that engine in 1919, it was replaced with two electrical motors. Pieces of equipment were turned on and off with shifter levers connected to the pulleys constructed of wood and metal. The shaft’s belts were made of buffalo hide so they were very strong.

Outside you can still see the 1903 outhouse. It hasn’t been removed as the building is on the National Historical Registry.

HOW THE WINDMILL WAS MADE

In the assembly area, you can see the head of an Eli windmill on a stub tower and learn how windmills were made on the original equipment. The Eli was an unusual design. It had no gears or any type of gear reduction. Instead it had a direct stroke, self-oiling design, and a ball-bearing swivel. Every time the Eli wheel turned, it pumped water. Its head locked in place during high winds. It was very simple to lubricate requiring only a cup of oil every three to six months. That was the only maintenance required. In the 1930s, it sold for $130. Some sold, just for the wheel, for $17.25.

In the windmill head assembly section, a sheet of galvanized steel was placed in an actuated cutter in order to cut blanks for the blades. Each blade was run through a roller to make the blade concave. This made it 87% more efficient than a wooden windmill. Making it of metal had other advantages. It was not as expensive and required less oil and paint.

The curved blade would be run through a crimper which made a double crimp on the blade’s tip, providing it with additional strength so it wouldn’t bend. An indentation in the shape of a dimple was put in. This step was necessary so that the outer rim piece would fit against the blade. The final machine riveted the inner and outer rim pieces to the windmill’s blades which completed the windmill’s head.

Windmills were built in sections with six blades to a section. Different size windmills had different size blades which varied the cost. A ten-foot windmill had 36 blades while an 8-1/2 foot windmill had 30 blades. Seventy-five percent of the windmills built were ten feet.

For the tower, the sheer punch called an iron worker, originally used in the shipping industry, was built around 1875. It took two people to operate. It enabled workers to cut heavy pieces of metal for the tower and also punch holes in the tower more quickly and accurately. To operate the punch, the employee would lift up the floor board revealing a bench seat where he would sit. He would then feed pieces into the punch via a lever on the side of the machine.

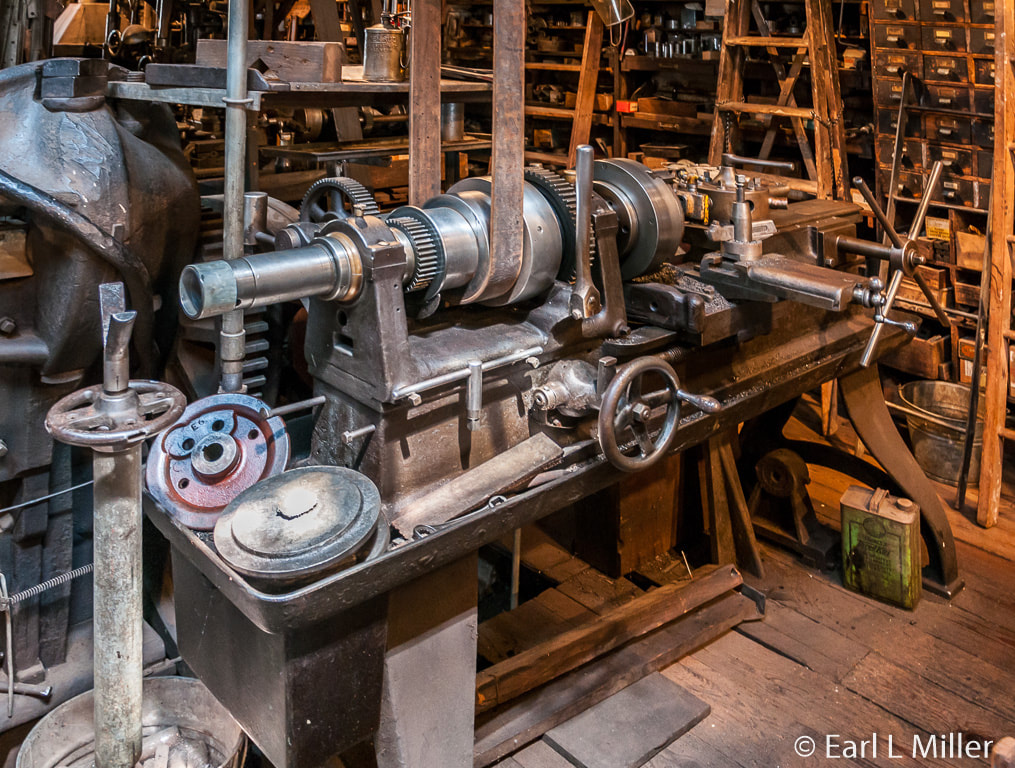

A turret lathe is the factory’s oldest piece of equipment, circa 1860, from Chicopee, Massachusetts. It would allow the worker to perform multiple tasks without having to reset the equipment. A spindle drill press allowed four different sizes of drill bits at one time. This saved time as the different drill bits didn’t have to be changed constantly.

It took about a week to assemble the windmill. Variables included the distance to the farm, height of the tower, and size of the wheel. Most tower sizes were 30 feet but some were 60 feet. Employees would complete the head, bring it to the farm, and assemble the windmill. It was then raised.The process was first done with horses and later by service trucks.

VISIBLE WINDMILL

Across the street from the museum, you’ll see a 35-foot, all steel Eli windmill that was produced in the 1920s. It has a ten-foot wheel and a 30-foot tower.

DETAILS

Kregel Windmill Factory Museum is located at 1416 Central Avenue in Nebraska City. Their telephone number is (402) 873-1078. Hours are closed Monday, Tuesday through Saturday 10:00 a.m. to 5:00 p.m., and on Sunday from 1:00 to 5:00 p.m. Admission is adults $8, students $5, children ages four and under are free. AAA/AARP/Veterans have a $1 discount. You can ask for a tour or take a self guided tour with the help of seven state of the art touch screens which explain the equipment and what you are seeing.

KIMMEL ORCHARD AND VINEYARD

If you want to learn about modern agriculture, head for Kimmel Orchard and Vineyard. It’s the place to pick your own produce, wander along trails, shop their store, take a hayrack ride, learn about apple production, or attend a festival.

Richard Kimmel grew up in Nebraska City. In 1925, he quit his job as a bank teller at Otoe National Bank in Nebraska City before establishing Kimmel Orchard. He also managed Kimmel Farms, established in the 1850s by his grandfather. His wife Laurine grew up with the Kimmels as neighbors. They married soon after he started the orchard. Their mission was to share the apples, tart cherries, and grapes they produced with their neighbors. While working together to build Kimmel Orchard, Laurine, who studied art at the University of Nebraska, became known nationally for her series of water color paintings titled “American Architecture.” They depicted old outhouses.

A German POW camp, located 30 miles away at Weeping Water, Nebraska, supplied the Orchard’s workers. Bill Oberdick, a German POW, was boss. He was caught defecting from Rommel. All of the POWs went back to Germany after the war except for Oberdick, who stayed on as the Orchard’s overseer. When Kimmel retired in 1967, he sold the orchard to Oberdick, who ran it for a number of years. When Oberdick retired, he sold it to his son-in-law, who, in turn, sold it to the Kimmel Foundation. The Orchard was renovated in 2000/2001.

Today the Orchard’s missions are agricultural educational research, historic preservation of the region’s orchard industry, and wholesome family experiences. The mission is to teach where food comes from and how important the fruit industry has been and continues to be in Nebraska.

In 2005, the Orchard built the Kimmel Education & Research Center in partnership with the University of Nebraska-Lincoln. The center houses research facilities, a food laboratory, meeting rooms, and offices. The university provides educational programs and helps partner events.

The orchard consists of 115 acres, 40 of which are in apple trees and eight in grapes. However, it also grows asparagus, strawberries, blackberries, Asian and regular pears, tart cherries, peaches, pumpkins, and gourds. Ninety percent of the produce is sold at the Orchard.

The Orchard traditionally grew 180 apple trees per acre with 15 feet between trees and 20 feet between the rows. Now they are mainly planting trees on dwarf root stock attached to trellises at 1,000 trees per acre. There are currently three feet between trees and 10-12 feet between rows. This has increased the yield per acre as compared to the older production. Under both methods, fruit is picked by hand.

U-PICK

Families are invited to explore the fields at leisure to pick fruits and vegetables from their source. U-Pick activities are seasonally dependent upon what is ripe with fruits and vegetables having different growing seasons.

The Orchard specializes in apples with 21 different varieties having harvesting dates from mid August through October. Each of the apples has their own characteristics when it comes to taste, color, and use such as eating or baking.

Apples vary in size because of the different species. At the Orchard, Lunchbox apples, less than two inches in diameter, are used for cider. The rest are sorted according to weight and size then hand inspected and graded. The machine is totally automatic, kicking out the bad apples with any defects. The best go for retail sale while the remainder are used for Kimmel pies and cider.

To make cider, the apples go through a grinder after they are washed. This resembles an applesauce which is pressed to extract all of the juices. The juice is filtered and purified then bottled, capped, and labeled. The rest (the pumice) is recycled.

OTHER PRODUCE

Markers at the end of rows help visitors identify what the produce is and what is in bloom. The Orchard supplies picking bags, helps weigh the fruit you purchase, and even pits the cherries. To participate, go to the red-roofed barn just north of the main buildings.

How are cherries pitted? They are sized in a rotating drum. When they reach the drum’s top, steel spikes push through the cherry to remove the pit while retaining the rest of the cherry. Cherries are bagged and returned to visitors or made into the Orchard’s cherry wine and pies.

Here is the fruit picking schedule for the other produce. This is for U-Pick and Pre Picked.

Strawberries Late May-Early June

Cherries Late June-Early July

Peaches Mid July-August

Blackberries Late July-Mid August prepicked only

Asian Pears Early September U-pick only

Pumpkins October

To learn about the different varieties, go their web site.

U-Pick hours are Saturday 9:00 a.m. to 4:00 p.m. and Sunday 11:00 a.m. to 4:00 p.m. in season. Admission prices for this activity are adults, 13 and older, $5; kids, ages 4 to 12, $3; seniors, 62 and older, $3; and military, active or retired, $3. Produce pricing is dependent on season and yield like the typical grocery store. It is purchased by the pound.

HAYRACK RIDES

These rides are included with your U-Pick/tree dome trail or event/festival admission and are available Saturdays and Sundays in September, October, and November. Your family can have a guided hayrack ride upon request. You’ll sit on hay bales as a farm tractor pulls the wagon on your tour.

NATURE TRAIL AND PLAYGROUND

The 1-1/2 mile interactive Tree Dome Nature Trail has informative signage and activities for children. Entrance to the trail is included in the U-Pick Admission. Along it, you will find Nebraska’s native plants. Be sure to notice the 170-year-old Eastern Cottonwood tree. You’ll also see animal track displays with corresponding animal descriptions, birdhouses, and waterfowl nests. The Orchard promotes wildlife observation from a young age.

The riparian area is home to lots of wildlife such as foxes, snapping turtles, deer, beavers, blue herons, geese, and wood ducks. At the pond, children can collect water samples to take to the research facility to check out microorganisms under microscopes firsthand.

Youngsters will also enjoy the Pollinator Playground consisting of two areas. One is for children ages 2 to 5 while the second is for youngsters ages 5 to 12. They’ll find a windmill slide and a child-sized Kimmel fruit stand.

THE APPLE BARN MARKET

The Market is known for its apple cider, apple doughnuts, and home-grown produce. However, lots of other products are also available. You can purchase dressings, homemade fudge, a variety of canned olives and canned vegetables, salsas, jams, jellies, pies, and popcorn. If that isn’t enough, they also have barbecue sauces, honey, syrups, and pre made mixes. It is closed January and February for maintenance. For details on their products, check out their web site.

Since the early 18th century, the area has grown premium grapes. The Orchard has been part of that scene since 1925 with six varieties of grapes. They offer fruit and grape wines which are made for them by Whiskey Run Creek Winery. Fresh pour sampling is only $5 for four selections, and you can keep the wine glass as a souvenir. See their site for information on wines.

FESTIVALS

The Orchard’s biggest festival is the Applejack Festival taking place September 20-22. The Apple Barn will be stocked with such treats as apple donuts, fresh cider, caramel apples, and apple pies. It will include live music, wine tastings, BBQ, face painting, and vendors. The Kimmel Education & Research Center will feature fun and educational activities for all ages. Other festivals are held throughout the year. For more information, visit their festival page.

TOURS

Individuals who want to learn about apple processing first hand can take a 30-minute tour which includes a showing of the apple sorting machine and cider production while providing an overview of the business and history of the facility. Processing takes place next to the café. The fee is five dollars.

DETAILS

Kimmel Orchard is located at 5995 G Rd, Nebraska City, Nebraska. Their telephone number is (402) 873-5293. Seasonal hours are March 1–December 23 Monday through Saturday: 9:00 a.m. to 5:00 p.m. and Sunday: 11 a.m. to 5 p.m. They do have an admission, as mentioned above, for U-Pick and the Tree Dome Nature Trail.

ARBOR DAY STATE HISTORICAL PARK

Due to a time shortage, we drove over to but did not tour the mansion owned by the founder of Arbor Day, J. Sterling Morton. From its beginnings as a four-room cabin in 1855, Morton expanded it to 30 rooms. His son Joy, president of Morton Salt Company in Chicago, grew it into a 52-room mansion that is a lookalike of the White House. Rooms house period as well as historical artifacts belonging to the Morton family.

The 72-acre park also includes an arboretum, an Italian terraced garden, a log cabin, a carriage house, walking trail, formal rose garden, and more than 200 varieties of lilacs. The log house is a memorial to the community’s settlers. A one-half mile tree trail winds through the original arboretum planted by the Mortons in the late 19th and early 20th centuries. The collection of trees and shrubs consist of more than 260 species including some that are native and some that are uncommon to the region. Many are labeled. The family gave the grounds to the Nebraska Game and Parks Commission in 1923. Grounds are open year round.

Picnicking is permitted in the area. Cider pressing and other old-time crafts take place the last two Sunday afternoons of September and the first two Sundays in October.

IT STARTED WITH TREES

Julius Sterling Morton, the founder of Arbor Day, was born in 1832 in Adams, New York. After obtaining his degree at the University of Michigan, he married his bride Caroline. They left for Nebraska the day they were married, settling in Nebraska City. He became the editor of the Nebraska News.

Morton was appointed Nebraska’s territorial Secretary of State from 1858 to 1861 by President James Buchanan and also served as the Acting Territorial Governor of Nebraska from 1858 to 1859. President Grover Cleveland appointed him as United States Secretary of Agriculture from 1893 to 1897. He supported Cleveland in setting up forest reservations.

At his home, Morton planted many rare varieties and heirloom apple trees. He instructed people in modern farming and forestry techniques. He believed trees would be effective windbreaks, protecting crops from erosion and overexposure to the sun. They would also provide fuel and building supplies. Morton promoted Arbor Day as a holiday to encourage the planting of trees.

He died in 1902. Nebraska donated a bronze statue of Morton to the National Statuary Hall Collection at the United States Capitol.

In 1872, the Nebraska State Board of Agriculture adopted Morton’s resolution to create Arbor Day. The first Arbor Day celebration occurred April 10, 1872 when more than a million trees were planted. During the 1880s, schools participated on Arbor Day by planting trees as memorials of historical events and to honor famous people. The state made it into a legal holiday in 1885. All other states, except Delaware, celebrated it within 20 years. Delaware eventually caved. Under Richard Nixon, it became a federal holiday on the last Friday in April. Alaska and Hawaii disregard the date since their planting schedules are a little different from the rest of the nation.

DETAILS

The park is located at 2611 Arbor Avenue, Nebraska City. The phone number is (402) 873-8717. Admission is adults $8, children ages 3-12 $6, children ages two and under free. Hours are Monday through Saturday 9:00 a.m. to 5:00 p.m. and on Sunday from 11:00 a.m. to 5:00 p.m.

RUNZA

If you are looking for a true Nebraska sandwich, head to Runza Drive Inn. Some commentators call it as Nebraskan as Cornhusker football. It is composed of a yeast dough bread pocket with a filling of beef, cabbage or sauerkraut, onions, and seasonings. They’re baked in various shapes ranging from a rectangle, a round, a square, to a triangle. The ones sold by Runza Drive Inn are rectangular. It is said to originate from a pierogi, a European dish of filled dumplings.

Not into a runza? The drive inn also sells hamburgers, french fries, onion rings, chili, salads, chicken strips, and cinnamon rolls. As of 2018, there are 85 Runza restaurants with 80 in Nebraska, two in Iowa, two in Kansas, and one in Colorado. You can find a Runza in Nebraska City at 702 S. 11th Street.

Kregel Windmill Factory Museum

The Office - Left Totally Undisturbed

The Forge

Demonstrating the Roller

Turret Lathe - Circa 1860s

Eli Windmill Head

35-Foot 1920s Eli Windmill

Kimmel Orchard and Winery

Traditional Method of Planting Apple Trees

New Apple Trees on Trellises

Fuji Apples - More Eastablished Trees Using the New Planting Method

Overall Shot of Kimmel Orchard's Apple Barn Market

Cider, a Popular Product at Kimmel Orchard's Apple Barn Market

Apple Doughnuts at Kimmel Orchard's Apple Barn Market

Arbor Day State Historical Park's Mansion - Home of J. Sterling Morton, Founder of Arbor Day