Hello Everyone,

Stopping by the stands and orchards throughout Palisade, Colorado during harvest season between the months of June to early October, has become very popular. Due to its unique climate and wonderful soil, the high quality fruit and vegetables grown here have become renowned.

Being farm country is not a new phenomenon for Palisade. As early as the 1890's. farmers planted apple, cherry, peach, pear, and plum trees. In 1909, the town celebrated its first Peach Day Festival with President Taft as the keynote speaker. Agritourism is now a major industry. However, it doesn’t stop with produce as hops, alpacas, and lavender are also raised.

Palisade is Colorado’s equivalent of Napa, California as visitors can visit 23 area wineries. These vintners provide many varieties of wine, both sweet and dry, and are known for unique wines using local fruits in their recipes. All provide a tasting of their products while some have a tour of their facility.

The town also holds special events related to its wine and agricultural industries. Starting the end of April, visitors can attend Wine Around Colorado or Barrel into Spring Wine Tasting. These two events are replicated in May. The Colorado Lavender Festival was held between July 7 to 9 this year while Palisade Peach Week occured August 17 through the 20th. On August 18 and 19, the town held their 49th Annual Peach Festival in the park. On September 14-17, the Colorado Mountain Winefest Festival in the park takes place.

From mid June to mid September, Palisade holds Sunday farmers markets from 9 a.m. to 1 p.m. on Third and Main Streets. It combines the sale of local fruits and vegetables with artisan demonstrations and crafts, live music, food, and chef demonstrations.

Although we were too early, in late May, to take advantage of Palisade’s delicious fruit, we did take the opportunity to tour Clark Family Orchards and Suncrest Orchard Alpacas. These are two farms definitely worth a visit.

Contact the Palisade Convention and Visitors Bureau and ask them to send you a copy of Palisade Colorado, Fruit and Wine Byway Agritour and Adventure. It lists the wineries and farms you can visit. You can order a copy at their web site.

CLARK FAMILY ORCHARDS

In 1897, James A. Clark, formerly of Iowa and Kansas, was one of the first fruit growers in Palisade. The orchards he started are now among the largest in the area. They consist of 100 acres where fruit is planted on the 120 acres of owned and leased ground. They’re run by Dennis and Staci Clark whose children make up the sixth generation. The Palisade area has 100 farms, but only five or six have ten acres or more.

The Clark’s primary crops are peaches and pears though they also raise cherries, apricots, plums, and alfalfa. They have 4,500 tomato plants and 1,000 pepper plants. The Clarks sell their produce across the state of Colorado as well as in Oklahoma and Texas.

We contacted Dennis for a tour of his farm and were very glad we did. We found him and his wife charming and very hospitable hosts. The Clarks offer free wagon tours of their farm pulled by two Belgian horses on Saturdays. We were there on a Tuesday, May 30, and Dennis was kind enough to hitch up his team so we could take the tour they offered.

The Clarks purchased their wagon during the fall of 2005. It was formerly used at Disney World and can hold 20 people comfortably. It’s used in the Palisade parades. As we traveled in the wagon throughout the farm, Dennis and Staci informed us of how they operated Clark Family Orchards.

Different fruits are ready for picking at various times. Here is the schedule:

Normally peaches are picked from June 22 until September 20, but due to weather conditions they were early this year.

Cherries are ready the first week of June.

Apricots can be harvested between mid June through mid July.

Plums are picked from July 1 through the first week of September.

Pears are ready for picking from August 1 to the first week of September.

The Clarks advised that migrants used to do the picking. They were farmers from other locales, transients, and hobos. Then Blacks from Arkansas did the work. Now they hire Mexicans who are legal workers and immigrant certified. The ones they hire can only work for Dennis. The Clarks furnish them with housing, rooming six men together, in quarters that are federally and state inspected.

Agriculture consists of perishable products and help needs to be hired when it’s needed. The Mexicans make themselves available. They prune, then return home to their families in Mexico, coming back for thinning and harvesting. Thinning consists of putting the trees five feet apart so the fruit isn’t overcrowded. All of the trees bud in the fall for next year’s crop.

In the old days, the Clarks used to have a lot more jobs for high school students. However, school now starts before Labor Day which interferes with harvesting.

Dennis pointed out the wind machines used for frost protection. The machines move air across an 800-foot-long surface. They move the cold air and bring in the warm air.

We saw several units of housing that had been built by the Civilian Conservation Corps during the 1940's. The CCC did mostly highway work. The Clarks brought these homes here which had been formerly used at Palisade’s River Bend Park.

Most of the irrigation is done by micro sprinklers located between the trees. The majority of the water comes from the Colorado River and is transported via major canal systems.

The Clarks don’t often rotate their crops. They do plant alfalfa to build organic materials into the soil. Peach trees that used to live 50 years, now live for 20 years. Pear trees live for 40 years, some for as long as 50 to 60 years.

After the wagon tour, we saw their fruit stand which hadn’t officially opened yet. It is now open daily from 8:00 a.m. to 6:00 p.m. Noticeable were all the photos of the six generations of Clarks which Dennis proudly showed off. Staci gave us a large tub of spreadable honey. We came away feeling that we had new friends in Palisade.

Agritourism is becoming important in Palisade which is a good thing. Many people don’t realize where the food on their tables comes from and how it is grown. Taking tours of such places of Clarks Family Orchards provides an understanding of how these farms operate and the hard work that is involved. Farmers work from sunrise to two to three hours after sunset.

You will find Clark Family Orchards at 3929 Highway 6 in Palisade. Their telephone number is (970) 464-0418.

SUNCREST ORCHARD ALPACAS AND FIBER WORKS

Besides seeing a farm that raises alpacas, visitors to Suncrest Orchard Alpacas and Fiber Works also find a company that specializes in fiber processing at their mini mill and making finished Alpaca products. When you visit the farm, you will learn how they do all of this and have an opportunity to buy products at their store.

Mike McDermott, the owner, advised us that It’s a small farm of ten acres that has been in the family for 42 years. Originally, it had all kinds of stock - six milk cows, 50 chickens, six pigs, a couple of goats, and four sheep when he was growing up on the farm. He went to Mesa State College where he majored in kinesiology. For many years he modified equipment for accessibility and mobility. He left that by buying the family farm where he has raised alpacas and grown peaches.

Peaches have to be picked by hand. The length of days in the Palisade area is ideal for ripening peaches. Weather is also conducive as the area doesn’t experience a severe winter cold since 26 degrees is the winter’s average.

He acquired his first alpacas in 2005. Alpacas are hypoallergenic so they were the only animals to which his wife, Cindy, wasn’t allergic. He also liked their behavior. Alpacas communicate with each other via body language. He has found out that if you go sideways toward them, they let you come close to them most of the time. If you go forward toward them, they view that as aggressive.

Not only is Alpaca fiber hypoallergenic, it is eight times warmer than wool. “It’s the fiber of the Gods according to the Incas,” Mike said.

Mike constructed every building on the property - the two barns, the processing building, and the store. He also remodeled the house. One of the barns is used for the girls with the other for the boys. To have control on breeding and aggression, the animals are segregated by sex 100% of the time.

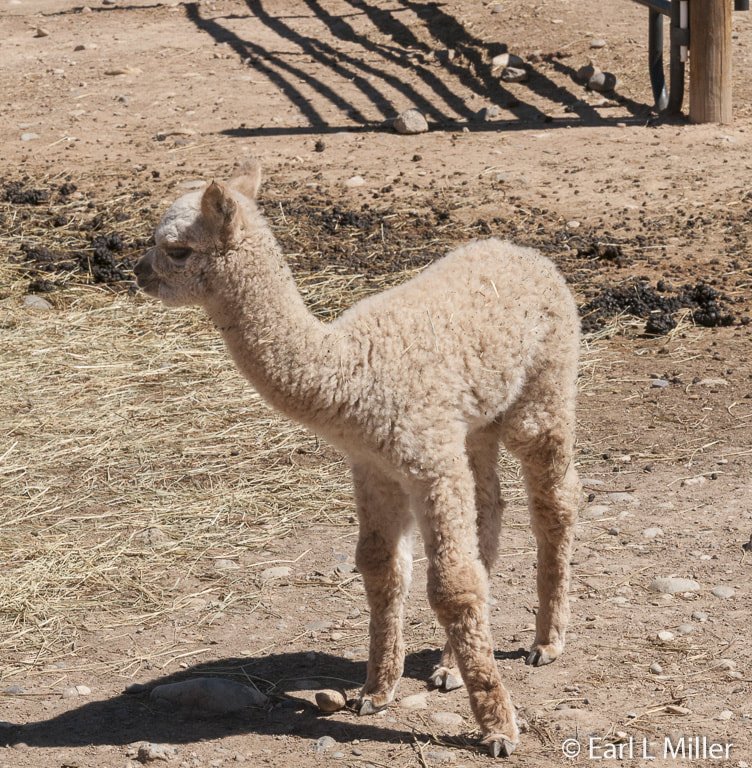

He introduced us to their alpacas. They have 22 boys and 29 girls of two different species. The Huacayas have hair that grows in a wave while Suri hair grows in a corkscrew. Hair grows approximately 3-1/2 inches in a year depending upon the animal’s age and health.

Breeders are trying to improve the fiber on the neck and legs. Hair is shorter on average in these places, and the aim is to try to grow all fibers the same length. The fiber is used to make yarn that’s used to create clothing like shawls, socks, and hats.

It takes 20 minutes to shear an animal with the process yielding, on average, four to six pounds of fiber per animal. Mike has three alpacas that yield close to 12 pounds. One of those is Avalanche, who is the alpha male. Alpacas have to be a year old to have fibers to harvest.

Alpacas eat 1-1/2 bales of hay a month and drink lots of water. They are also fed multi vitamin pellets. The animals have three stomachs like sheep and goats. Mike performs surgery on the alpacas in the barns and tries to do his own vetting. His background as a physical therapist has proven useful with medical issues.

All of the animals have names even the (Crias) babies. He has tried to name his animals after varieties of peach trees with only a few exceptions. One he named Santa because it looks like it has a beard. Valentine received its name because it was born on Valentine’s Day.

We spotted a baby and his mother. “That’s Rocket Man,” said Mike. “His mom is Laurie Ann.”

The average age of his animals is nine with six under a year old. The boys' ages are between 1-1/2 to 12 years old while most of the girls are ten years old. There is a female baby and four or five that are two to three years old.

Domesticated alpacas live for 25 years while those in South America, in the wild, live for about 12 to 15 years. The domestic animals live longer because of good nutrition and because the animal’s bite is managed better.

About 40,000 to 45,000 alpacas were imported between 1984 and 1997 from South America. These animals trace to the Incas, who created them from a cross between llamas and vicuñas, a South American based camelid. They’re related to camels and guanacos.

Current breeders are yet to get the yield that the Incas did. The Spanish bred them for meat, messing up the fiber. Now the national average for fiber in the United States surpasses Peru and Chili. There are approximately 420,000 animals in the U.S. At the farm, they are raised for fiber though Mike does butcher them for meat when he no longer can use their fiber. They are his main meat source.

We noticed two large dogs near the male barn. The eight-year-old is a Maremma Sheepdog while the eight-month-old dog is a Heinz 57. The puppy is still learning that the animals are its charges. They are there to protect the alpacas from neighbors’ dogs to wildlife. Stressing alpacas can cause them to lose pregnancies and can create tenderness in the fleeces which is not good for production.

“I haven’t lost an animal since I got the dogs,” said Mike. “ Working together the dogs can take on and kill a bear or mountain lion.”

MILL TOUR

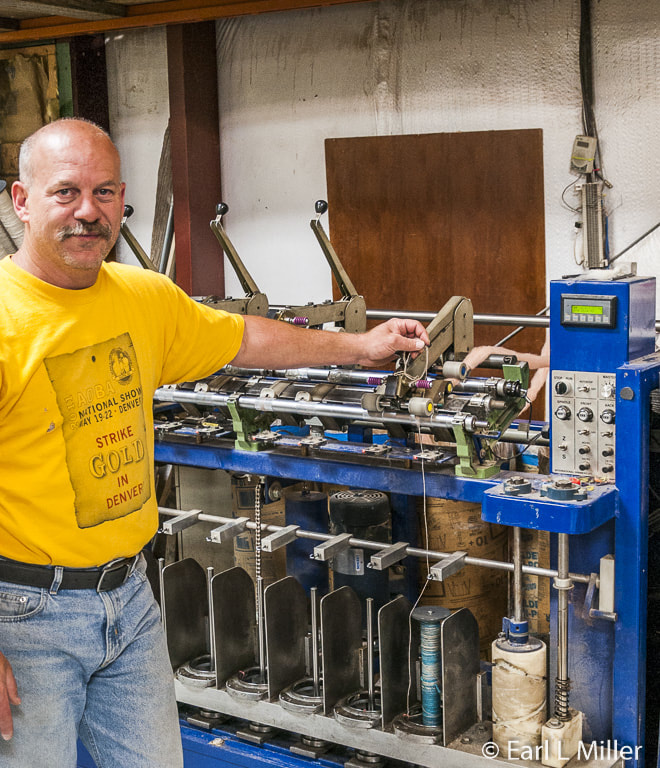

We next had a tour of the Belfast mini mill. It is set up to be capable of producing batts, rovings, felted sheets, rug yarn, and yarns of different sizes and plies as well as provide custom dye services. Mike is planning on purchasing a knitting machine in September so he can go commercial with his Alpaca products. He and Cindy as well as his assistant, Laurie Clark, do hand knitting currently.

Mike told us that there are 16 natural colors. He blends colors together and has found that the fiber takes well to the colors. He has three blacks, three whites, three fawns, three browns, three gray/silver grays, and two rose grays. He has found that Alpacas, like all animals, including humans, change hair color as they age.

More than 250 farms send Mike raw fiber. His goal is to help the industry. When he started, he processed his fiber by hand then progressed to the commercial mill. Now Colorado has five mills like the one we were seeing. Mike processes natural fibers in all different sizes and plies.

He first washes it in washing machines using the spin cycle only. It takes 3-1/2 hours to wash. Then the fiber is put in dryer bins and air dried for 24 hours, using no heat, as that breaks down the fiber.

It now goes through the picker. It opens up the fiber structures and helps separate the vegetation out of the fleece. Then the fiber is sprayed with a conditioner and placed into a plastic tub. The fiber is left in the tubs for a time so the conditioner permeates all of it.

It then goes through a separator which separates the coarse from the fine fibers. All goes through a series of wheels. It drops the vegetation and coarse fibers. Fine fibers come out at the end of the machine. When the separator concludes, the preparation is finished.

The next part of the process is the carder. Here fibers are combed into a sliver. The machine has 14 wheels to comb the fibers. It produces three types of products: rug yarn, batting for quilting, and regular yarn.

The drafter finishes preparing the fiber for spinning. The slivers are stretched 2-1/2 times while paired with other slivers to achieve the desired thickness. The standard pass of one hundred yards at the beginning becomes 500 yards.

Cindy and Laurie choose the colors then Cindy dyes the yarn. I saw ones with two and three different colors combined. For example, there was one that had pink and green.

Spinning is the same process as set up at all mills. It stretches the yarn further and twists it depending upon its future use. Suncrest Orchard spinners can do 12 spindles at one time. It does up to four pounds of fiber in an hour depending on the size of the yarn.

The plyer puts the single strands of yarn together. Standard for natural yarns are two, three, or four plies. The yarn is then put through a steamer to help set the twist and relax the fibers to the natural state creating the yarn’s loft.

The skein winder winds the yarn into skeins for final use.

To prepare one bag of fiber, three pounds, the whole process takes 63 hours of work. Mike then sends the yarn back to the farms in a cone or skein depending on what they want. Laurie, Cindy, and Mike knit and crochet with their own fiber making products for their shop. Mike has been knitting since he was ten.

Cindy and Mike make 80% of the items in the shop. These include scarves, shawls, and hats. Mike hopes to make socks. Visitors can also purchase items on line.

All items in the shop, except for three of them, are made in the United States. Those three are stuffed alpacas from China, wooden alpacas from China, and black jackets from Peru.

If you are in Palisade the third week of May, stop by Suncrest Orchard Alpacas and watch Mike shear his animals.

You’ll find Suncrest Orchard Alpacas and Fiber Works at 3608 E. 1/4 Road in Palisade. Their telephone number is (907) 464-4862. Call Mike and make an appointment to see the alpacas and tour their mini mill. Admission is free with hours from 9:00 a.m. to 5:00 p.m. Tuesday through Saturday. They are open year round.

Stopping by the stands and orchards throughout Palisade, Colorado during harvest season between the months of June to early October, has become very popular. Due to its unique climate and wonderful soil, the high quality fruit and vegetables grown here have become renowned.

Being farm country is not a new phenomenon for Palisade. As early as the 1890's. farmers planted apple, cherry, peach, pear, and plum trees. In 1909, the town celebrated its first Peach Day Festival with President Taft as the keynote speaker. Agritourism is now a major industry. However, it doesn’t stop with produce as hops, alpacas, and lavender are also raised.

Palisade is Colorado’s equivalent of Napa, California as visitors can visit 23 area wineries. These vintners provide many varieties of wine, both sweet and dry, and are known for unique wines using local fruits in their recipes. All provide a tasting of their products while some have a tour of their facility.

The town also holds special events related to its wine and agricultural industries. Starting the end of April, visitors can attend Wine Around Colorado or Barrel into Spring Wine Tasting. These two events are replicated in May. The Colorado Lavender Festival was held between July 7 to 9 this year while Palisade Peach Week occured August 17 through the 20th. On August 18 and 19, the town held their 49th Annual Peach Festival in the park. On September 14-17, the Colorado Mountain Winefest Festival in the park takes place.

From mid June to mid September, Palisade holds Sunday farmers markets from 9 a.m. to 1 p.m. on Third and Main Streets. It combines the sale of local fruits and vegetables with artisan demonstrations and crafts, live music, food, and chef demonstrations.

Although we were too early, in late May, to take advantage of Palisade’s delicious fruit, we did take the opportunity to tour Clark Family Orchards and Suncrest Orchard Alpacas. These are two farms definitely worth a visit.

Contact the Palisade Convention and Visitors Bureau and ask them to send you a copy of Palisade Colorado, Fruit and Wine Byway Agritour and Adventure. It lists the wineries and farms you can visit. You can order a copy at their web site.

CLARK FAMILY ORCHARDS

In 1897, James A. Clark, formerly of Iowa and Kansas, was one of the first fruit growers in Palisade. The orchards he started are now among the largest in the area. They consist of 100 acres where fruit is planted on the 120 acres of owned and leased ground. They’re run by Dennis and Staci Clark whose children make up the sixth generation. The Palisade area has 100 farms, but only five or six have ten acres or more.

The Clark’s primary crops are peaches and pears though they also raise cherries, apricots, plums, and alfalfa. They have 4,500 tomato plants and 1,000 pepper plants. The Clarks sell their produce across the state of Colorado as well as in Oklahoma and Texas.

We contacted Dennis for a tour of his farm and were very glad we did. We found him and his wife charming and very hospitable hosts. The Clarks offer free wagon tours of their farm pulled by two Belgian horses on Saturdays. We were there on a Tuesday, May 30, and Dennis was kind enough to hitch up his team so we could take the tour they offered.

The Clarks purchased their wagon during the fall of 2005. It was formerly used at Disney World and can hold 20 people comfortably. It’s used in the Palisade parades. As we traveled in the wagon throughout the farm, Dennis and Staci informed us of how they operated Clark Family Orchards.

Different fruits are ready for picking at various times. Here is the schedule:

Normally peaches are picked from June 22 until September 20, but due to weather conditions they were early this year.

Cherries are ready the first week of June.

Apricots can be harvested between mid June through mid July.

Plums are picked from July 1 through the first week of September.

Pears are ready for picking from August 1 to the first week of September.

The Clarks advised that migrants used to do the picking. They were farmers from other locales, transients, and hobos. Then Blacks from Arkansas did the work. Now they hire Mexicans who are legal workers and immigrant certified. The ones they hire can only work for Dennis. The Clarks furnish them with housing, rooming six men together, in quarters that are federally and state inspected.

Agriculture consists of perishable products and help needs to be hired when it’s needed. The Mexicans make themselves available. They prune, then return home to their families in Mexico, coming back for thinning and harvesting. Thinning consists of putting the trees five feet apart so the fruit isn’t overcrowded. All of the trees bud in the fall for next year’s crop.

In the old days, the Clarks used to have a lot more jobs for high school students. However, school now starts before Labor Day which interferes with harvesting.

Dennis pointed out the wind machines used for frost protection. The machines move air across an 800-foot-long surface. They move the cold air and bring in the warm air.

We saw several units of housing that had been built by the Civilian Conservation Corps during the 1940's. The CCC did mostly highway work. The Clarks brought these homes here which had been formerly used at Palisade’s River Bend Park.

Most of the irrigation is done by micro sprinklers located between the trees. The majority of the water comes from the Colorado River and is transported via major canal systems.

The Clarks don’t often rotate their crops. They do plant alfalfa to build organic materials into the soil. Peach trees that used to live 50 years, now live for 20 years. Pear trees live for 40 years, some for as long as 50 to 60 years.

After the wagon tour, we saw their fruit stand which hadn’t officially opened yet. It is now open daily from 8:00 a.m. to 6:00 p.m. Noticeable were all the photos of the six generations of Clarks which Dennis proudly showed off. Staci gave us a large tub of spreadable honey. We came away feeling that we had new friends in Palisade.

Agritourism is becoming important in Palisade which is a good thing. Many people don’t realize where the food on their tables comes from and how it is grown. Taking tours of such places of Clarks Family Orchards provides an understanding of how these farms operate and the hard work that is involved. Farmers work from sunrise to two to three hours after sunset.

You will find Clark Family Orchards at 3929 Highway 6 in Palisade. Their telephone number is (970) 464-0418.

SUNCREST ORCHARD ALPACAS AND FIBER WORKS

Besides seeing a farm that raises alpacas, visitors to Suncrest Orchard Alpacas and Fiber Works also find a company that specializes in fiber processing at their mini mill and making finished Alpaca products. When you visit the farm, you will learn how they do all of this and have an opportunity to buy products at their store.

Mike McDermott, the owner, advised us that It’s a small farm of ten acres that has been in the family for 42 years. Originally, it had all kinds of stock - six milk cows, 50 chickens, six pigs, a couple of goats, and four sheep when he was growing up on the farm. He went to Mesa State College where he majored in kinesiology. For many years he modified equipment for accessibility and mobility. He left that by buying the family farm where he has raised alpacas and grown peaches.

Peaches have to be picked by hand. The length of days in the Palisade area is ideal for ripening peaches. Weather is also conducive as the area doesn’t experience a severe winter cold since 26 degrees is the winter’s average.

He acquired his first alpacas in 2005. Alpacas are hypoallergenic so they were the only animals to which his wife, Cindy, wasn’t allergic. He also liked their behavior. Alpacas communicate with each other via body language. He has found out that if you go sideways toward them, they let you come close to them most of the time. If you go forward toward them, they view that as aggressive.

Not only is Alpaca fiber hypoallergenic, it is eight times warmer than wool. “It’s the fiber of the Gods according to the Incas,” Mike said.

Mike constructed every building on the property - the two barns, the processing building, and the store. He also remodeled the house. One of the barns is used for the girls with the other for the boys. To have control on breeding and aggression, the animals are segregated by sex 100% of the time.

He introduced us to their alpacas. They have 22 boys and 29 girls of two different species. The Huacayas have hair that grows in a wave while Suri hair grows in a corkscrew. Hair grows approximately 3-1/2 inches in a year depending upon the animal’s age and health.

Breeders are trying to improve the fiber on the neck and legs. Hair is shorter on average in these places, and the aim is to try to grow all fibers the same length. The fiber is used to make yarn that’s used to create clothing like shawls, socks, and hats.

It takes 20 minutes to shear an animal with the process yielding, on average, four to six pounds of fiber per animal. Mike has three alpacas that yield close to 12 pounds. One of those is Avalanche, who is the alpha male. Alpacas have to be a year old to have fibers to harvest.

Alpacas eat 1-1/2 bales of hay a month and drink lots of water. They are also fed multi vitamin pellets. The animals have three stomachs like sheep and goats. Mike performs surgery on the alpacas in the barns and tries to do his own vetting. His background as a physical therapist has proven useful with medical issues.

All of the animals have names even the (Crias) babies. He has tried to name his animals after varieties of peach trees with only a few exceptions. One he named Santa because it looks like it has a beard. Valentine received its name because it was born on Valentine’s Day.

We spotted a baby and his mother. “That’s Rocket Man,” said Mike. “His mom is Laurie Ann.”

The average age of his animals is nine with six under a year old. The boys' ages are between 1-1/2 to 12 years old while most of the girls are ten years old. There is a female baby and four or five that are two to three years old.

Domesticated alpacas live for 25 years while those in South America, in the wild, live for about 12 to 15 years. The domestic animals live longer because of good nutrition and because the animal’s bite is managed better.

About 40,000 to 45,000 alpacas were imported between 1984 and 1997 from South America. These animals trace to the Incas, who created them from a cross between llamas and vicuñas, a South American based camelid. They’re related to camels and guanacos.

Current breeders are yet to get the yield that the Incas did. The Spanish bred them for meat, messing up the fiber. Now the national average for fiber in the United States surpasses Peru and Chili. There are approximately 420,000 animals in the U.S. At the farm, they are raised for fiber though Mike does butcher them for meat when he no longer can use their fiber. They are his main meat source.

We noticed two large dogs near the male barn. The eight-year-old is a Maremma Sheepdog while the eight-month-old dog is a Heinz 57. The puppy is still learning that the animals are its charges. They are there to protect the alpacas from neighbors’ dogs to wildlife. Stressing alpacas can cause them to lose pregnancies and can create tenderness in the fleeces which is not good for production.

“I haven’t lost an animal since I got the dogs,” said Mike. “ Working together the dogs can take on and kill a bear or mountain lion.”

MILL TOUR

We next had a tour of the Belfast mini mill. It is set up to be capable of producing batts, rovings, felted sheets, rug yarn, and yarns of different sizes and plies as well as provide custom dye services. Mike is planning on purchasing a knitting machine in September so he can go commercial with his Alpaca products. He and Cindy as well as his assistant, Laurie Clark, do hand knitting currently.

Mike told us that there are 16 natural colors. He blends colors together and has found that the fiber takes well to the colors. He has three blacks, three whites, three fawns, three browns, three gray/silver grays, and two rose grays. He has found that Alpacas, like all animals, including humans, change hair color as they age.

More than 250 farms send Mike raw fiber. His goal is to help the industry. When he started, he processed his fiber by hand then progressed to the commercial mill. Now Colorado has five mills like the one we were seeing. Mike processes natural fibers in all different sizes and plies.

He first washes it in washing machines using the spin cycle only. It takes 3-1/2 hours to wash. Then the fiber is put in dryer bins and air dried for 24 hours, using no heat, as that breaks down the fiber.

It now goes through the picker. It opens up the fiber structures and helps separate the vegetation out of the fleece. Then the fiber is sprayed with a conditioner and placed into a plastic tub. The fiber is left in the tubs for a time so the conditioner permeates all of it.

It then goes through a separator which separates the coarse from the fine fibers. All goes through a series of wheels. It drops the vegetation and coarse fibers. Fine fibers come out at the end of the machine. When the separator concludes, the preparation is finished.

The next part of the process is the carder. Here fibers are combed into a sliver. The machine has 14 wheels to comb the fibers. It produces three types of products: rug yarn, batting for quilting, and regular yarn.

The drafter finishes preparing the fiber for spinning. The slivers are stretched 2-1/2 times while paired with other slivers to achieve the desired thickness. The standard pass of one hundred yards at the beginning becomes 500 yards.

Cindy and Laurie choose the colors then Cindy dyes the yarn. I saw ones with two and three different colors combined. For example, there was one that had pink and green.

Spinning is the same process as set up at all mills. It stretches the yarn further and twists it depending upon its future use. Suncrest Orchard spinners can do 12 spindles at one time. It does up to four pounds of fiber in an hour depending on the size of the yarn.

The plyer puts the single strands of yarn together. Standard for natural yarns are two, three, or four plies. The yarn is then put through a steamer to help set the twist and relax the fibers to the natural state creating the yarn’s loft.

The skein winder winds the yarn into skeins for final use.

To prepare one bag of fiber, three pounds, the whole process takes 63 hours of work. Mike then sends the yarn back to the farms in a cone or skein depending on what they want. Laurie, Cindy, and Mike knit and crochet with their own fiber making products for their shop. Mike has been knitting since he was ten.

Cindy and Mike make 80% of the items in the shop. These include scarves, shawls, and hats. Mike hopes to make socks. Visitors can also purchase items on line.

All items in the shop, except for three of them, are made in the United States. Those three are stuffed alpacas from China, wooden alpacas from China, and black jackets from Peru.

If you are in Palisade the third week of May, stop by Suncrest Orchard Alpacas and watch Mike shear his animals.

You’ll find Suncrest Orchard Alpacas and Fiber Works at 3608 E. 1/4 Road in Palisade. Their telephone number is (907) 464-4862. Call Mike and make an appointment to see the alpacas and tour their mini mill. Admission is free with hours from 9:00 a.m. to 5:00 p.m. Tuesday through Saturday. They are open year round.

Clark Family Orchards

CCC Housing

Irrigation of the Orchards

Pear Trees

The Clark's Horse Drawn Cart

Rocket Man

Some of Mike's Alpacas

Another Look

Close Up

A Sheared Alpaca

Washing Process

The Dryer

The Separator

Laurie Clark at the Carder

Mike at the Spinner

The Plyer

Spools of Fiber

The Shop at Suncrest Orchard Alpacas and Fiber Works